- 08

- Nov

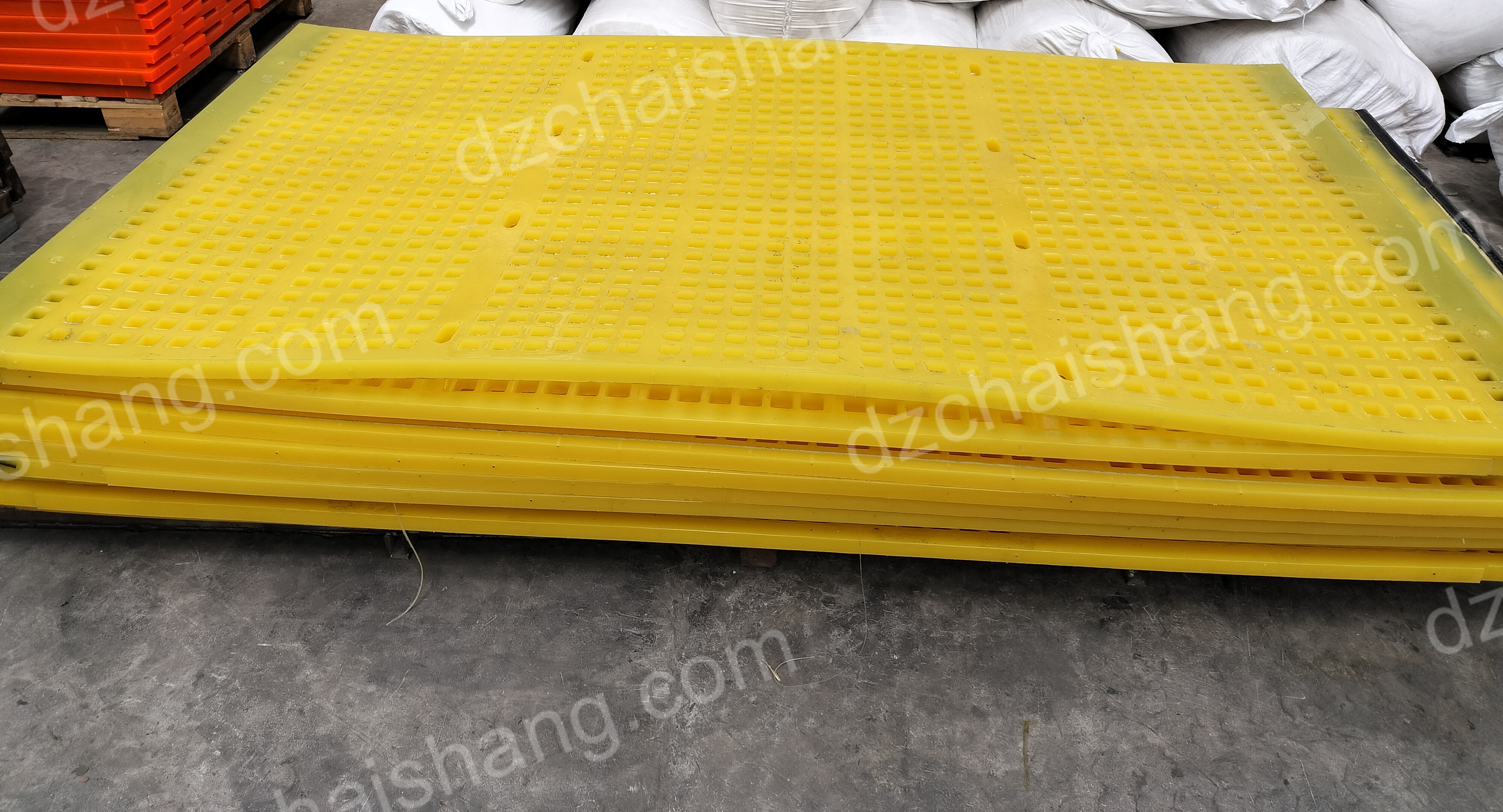

What is the difference between polyurethane screens and traditional screens?

We all know that polyurethane screen mesh is a common type of screen mesh. With the continuous development of my country’s screening industry, the application of polyurethane screening is becoming more and more widespread. What are the characteristics of polyurethane screen? What is the difference between it and traditional screen? Let’s find out today!

Traditional mining precision screens generally use metal screens or injected nylon screens. Due to poor wear resistance and corrosion resistance, metal braided mesh requires high replacement frequency, high labor intensity, high cost, poor elasticity of the metal mesh, and fixed mesh size.

During screening, the screen holes are easily blocked, which affects the screening power and makes the noise louder during operation. Nylon precision screens are injection molded from thermoplastic nylon. Due to the limitations of the thermoplastic molecular injection molding process, large monolithic screens cannot be produced. When used, it can only be spliced by multiple small-sized screens. Due to defects such as large splicing gaps and screen separators, the screen opening is low, usually less than 10%, and the screen power is very low.

Polyurethane screens make up for the shortcomings of traditional screens. It has the advantages of large scale, good elasticity, wear resistance, light weight, long service life, low noise, and no splicing during use. The current polyurethane screen has large sieve holes and low scale accuracy. It is only suitable for rough selection of materials, not suitable for selection.