- 27

- Nov

Things to note when making polyurethane screen plates

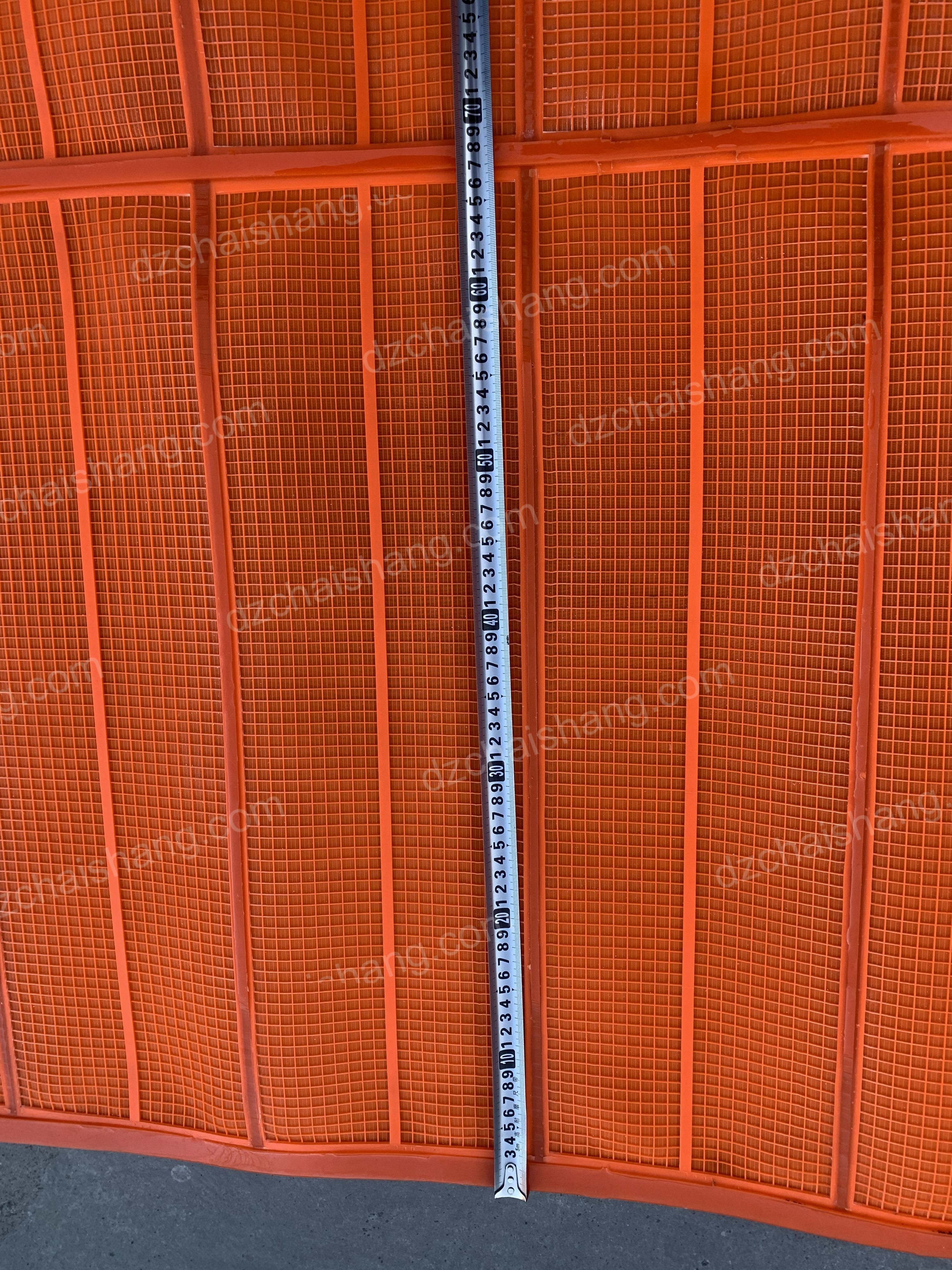

The mesh hole forming of polyurethane sieve plate is an important part of the sieve plate making process. The sieve plate will be affected by many factors during the production and molding process. The first thing to pay attention to is the influence of the properties of the material on the screening. The formation of the sieve plate first To determine the pore size of the sieve holes, select the appropriate pore size to make the sieve plate according to the particle size of the material to be screened.

Secondly, the factor that affects the shape of the sieve plate is the adjustment method of the mold used in the production of the sieve plate. The relative position of the sieve plate polishing tool and the relative position of the mold above and below the guide rail curve are determined by the guide rail device. Generally, the relative position on the press. Adjust the press connecting rod length accordingly.

When forming the sieve plate, it is easy to cause the sieve plate to be blocked, so pay attention to the opening direction when processing, with small holes upward and large holes downward. If clogging occurs, the process needs to be modified and a grinding elevator added to allow finer-grained materials to enter the mill directly. These aspects should be paid attention to during this process.

The sieve plate should be used reasonably and correctly, so the sieve plate can play a greater role. Therefore, please note the following:

1. Increase the pattern on the surface of the screen plate. If there are slight scratches or small dents, they will not be obvious.

2. Reduce shrinkage of screen metal roofing materials. With large decking, metal roofing materials will shrink because even when stretched, the flat surface is difficult to straighten completely.