- 28

- Nov

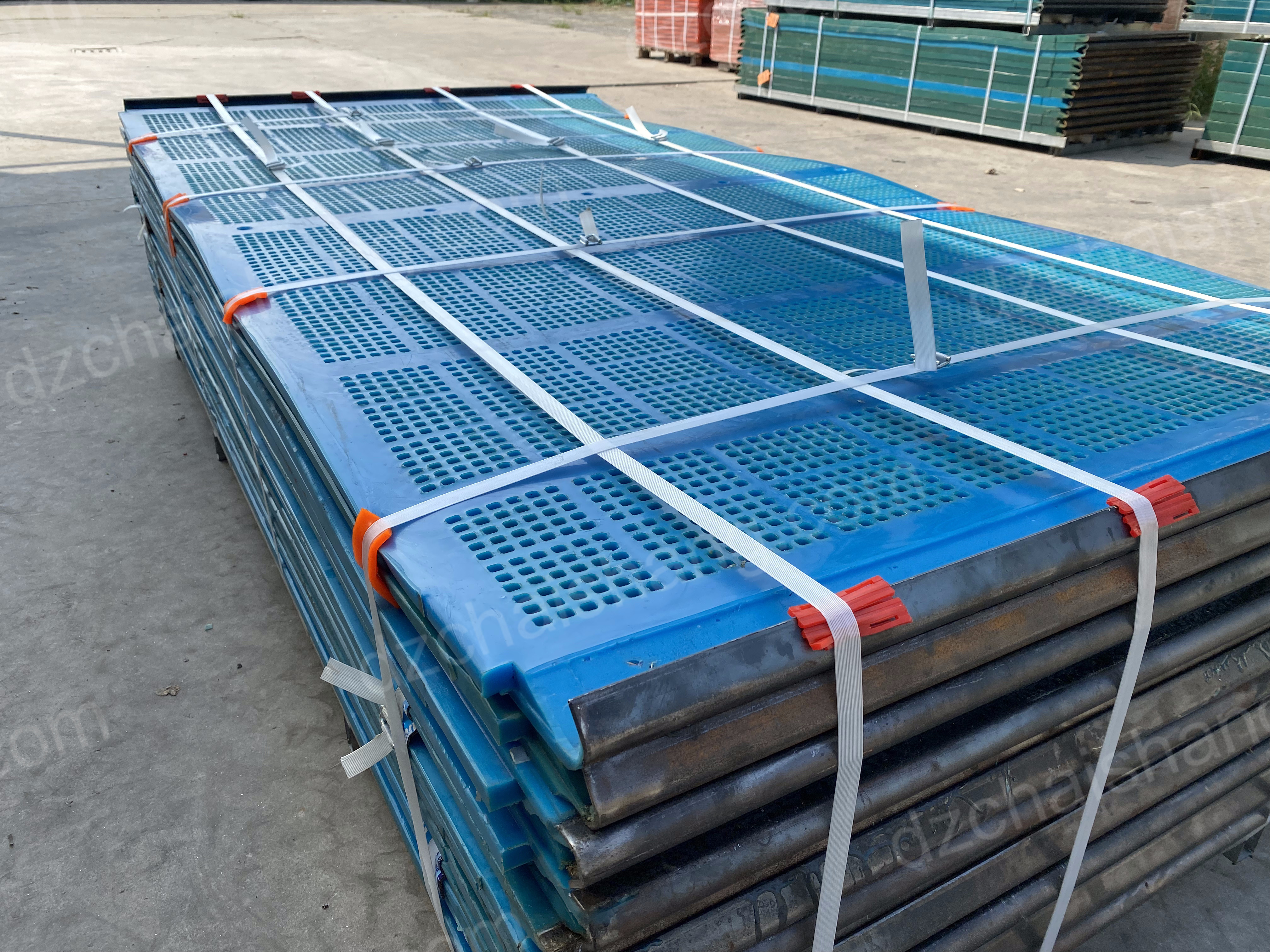

Detailed introduction of polyurethane screen plate and its core work

The raw materials for the production of polyurethane sieve plates can reduce the friction coefficient between the sieve plate and the material, which can further promote the penetration of the sieve plate, improve screening efficiency, and avoid the adhesion of wet particles. At the same time, the friction coefficient is reduced, thereby reducing wear, extending service life, corrosion resistance, non-flammable, non-toxic and odorless.

Due to the reasonable design of the screen plate and the manufacturing process of the screen plate, the screened material particles will not block the screen holes. It has excellent vibration absorption capacity and strong noise elimination ability, which reduces noise and makes objects on the screen surface less likely to break during vibration.

Understanding polyurethane screen plates can reduce unnecessary troubles in our work and use. Polyurethane elastomer screen plates have excellent wear resistance and long service life. They are more than 10 times that of metal wire mesh and 3 to 5 times that of ordinary rubber plates. , 2 to 3 times that of stainless steel plates.

The production of polyurethane screen plates is very precise. There are two casting methods, one is mechanical casting. This manufacturing method uses mechanical power for processing, which saves a lot of time and energy, and can achieve mass production. The polyurethane sieve plates are mixed evenly and do not produce bubbles. It is a commonly used manufacturing method.

The second is manual casting. This method is flexible. Your own hands are definitely more flexible than machines. It can help users save resources, but one thing is that it takes a long time. Due to the screening effect of polyurethane screens, polyurethane screen plates play an important role in production and life.

Let’s take a look at the core work of the polyurethane screen plate: The polyurethane screen plate is an important core component of the screening equipment. When the vibrating screen vibrates, the materials will be placed on the screen plates of different sizes and different apertures. Under the action of external forces, the materials will be different. Large and small materials are separated to achieve the purpose of classification and screening.