- 11

- Dec

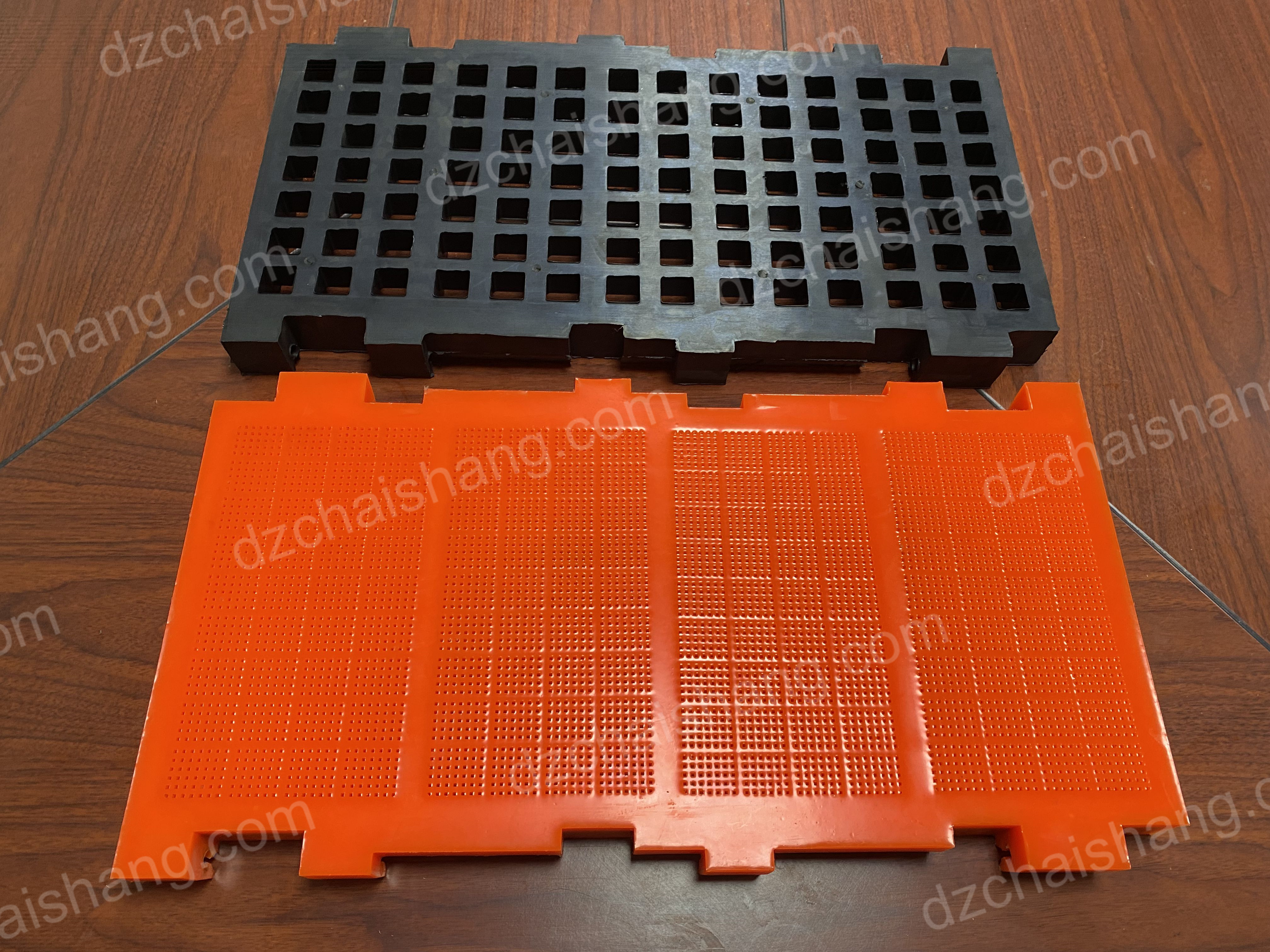

As a mining user, what are the benefits of using polyurethane screens for machine screening?

1. It can work for a long time and has great endurance. Because the polyurethane elastic screen uses steel wire rope as the structural material, and polyurethane has a certain amount of elasticity, which will greatly slow down the force generated by vibration and is very wear-resistant, so it has great elasticity and the endurance is that of a rubber screen. net more than twice.

2. Outstanding work ability. The screen surface has an automatic cleaning function, so there will be no clogging. Polyurethane has a high affinity for water, and the mesh angle is about 140°, so it can greatly reduce the adhesion of wet particles and other particles. Therefore, it is suitable for hierarchical classification of granular materials.

3. Particulate matter has distinct layers. The production process of polyurethane screens uses mold infusion molding technology, with precise hole spacing and high work efficiency.

4. It has a wide range of uses, is more technical, and can be freely customized. Polyurethane screens are generally used in petrochemical industry, coal washing and mining areas.

5. It is simple to install and maintain, has a wide range of applications and is made of lightweight material. On-site operation and replacement are extremely convenient without affecting work efficiency. The product has good noise reduction effect and can give workers a quiet working environment.