- 13

- Dec

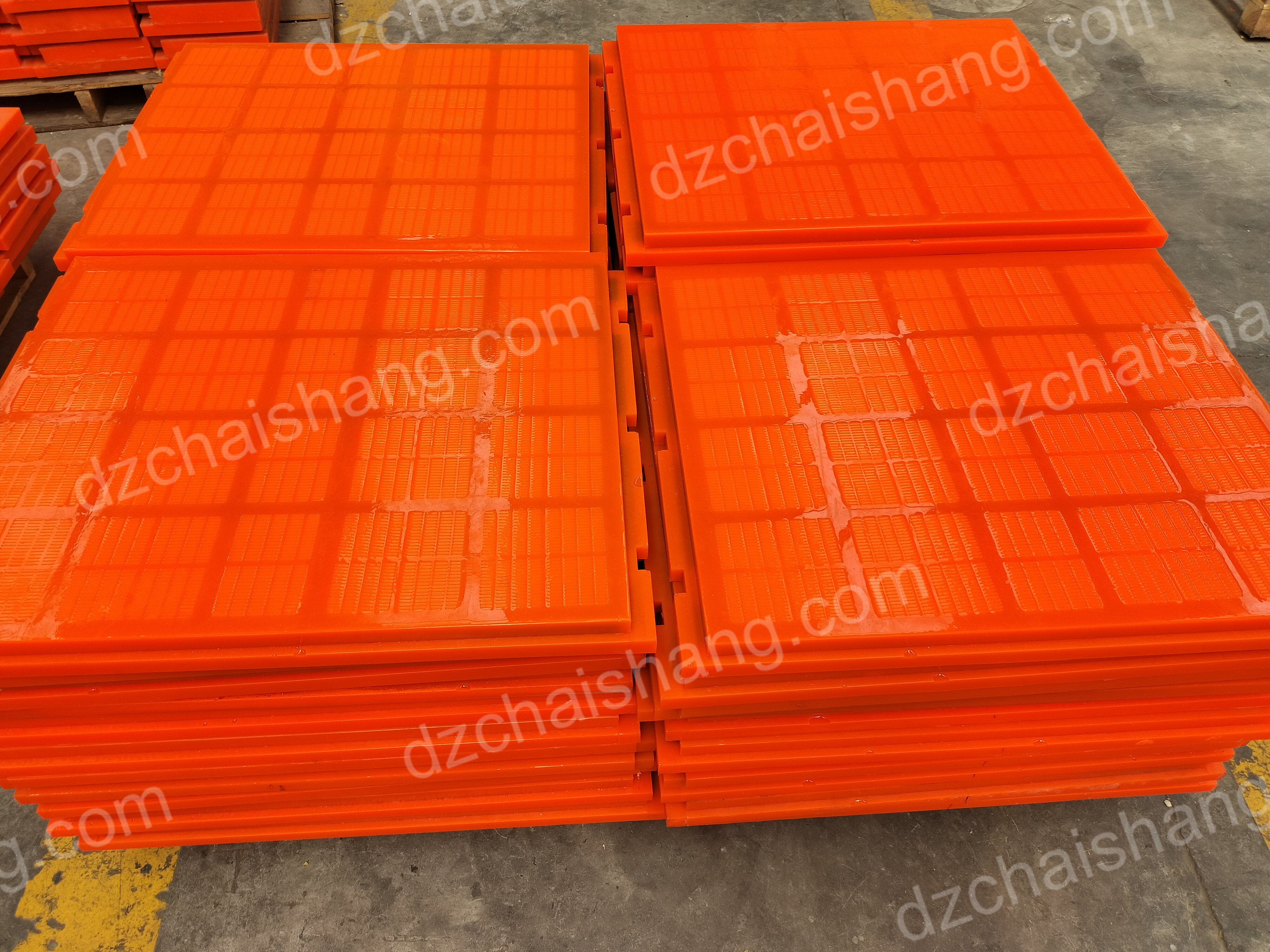

How to choose when purchasing “Polyurethane Screen”

1. When choosing a polyurethane screen, you must first ensure that the mesh openings are uniform. High-quality polyurethane mesh has uniform openings, small errors, and meets standards.

2. Look at the aperture ratio of the polyurethane screen. The opening rate is the most direct factor affecting the screening force. The more mesh holes the polyurethane screen has, the higher the opening rate, the greater the screening force, and the greater the output.

3. Check the polyurethane screen connection. The connection method of the polyurethane screen directly affects the screening power of the screen. More convenient disassembly and assembly can shorten the initial assembly time and use part of the screen replacement time, thereby increasing power consumption. Polyurethane screens must be tightly connected to each other to prevent leakage and ensure quality.

4. High-quality polyurethane screens must be both high-strength and soft. In fact, polyurethane screens must be very flexible in order to ensure that the cost is not compromised. Polyurethane screens must have a certain degree of toughness to prevent cracking.

5. When choosing a polyurethane screen, check its appearance. No matter whether the appearance of the polyurethane screen is exquisite or not, no matter whether the screen is flat or not, the polyurethane screen has simple color, torn edges, burrs or lack of material. , mixing, high-density joints and other phenomena.