- 14

- Dec

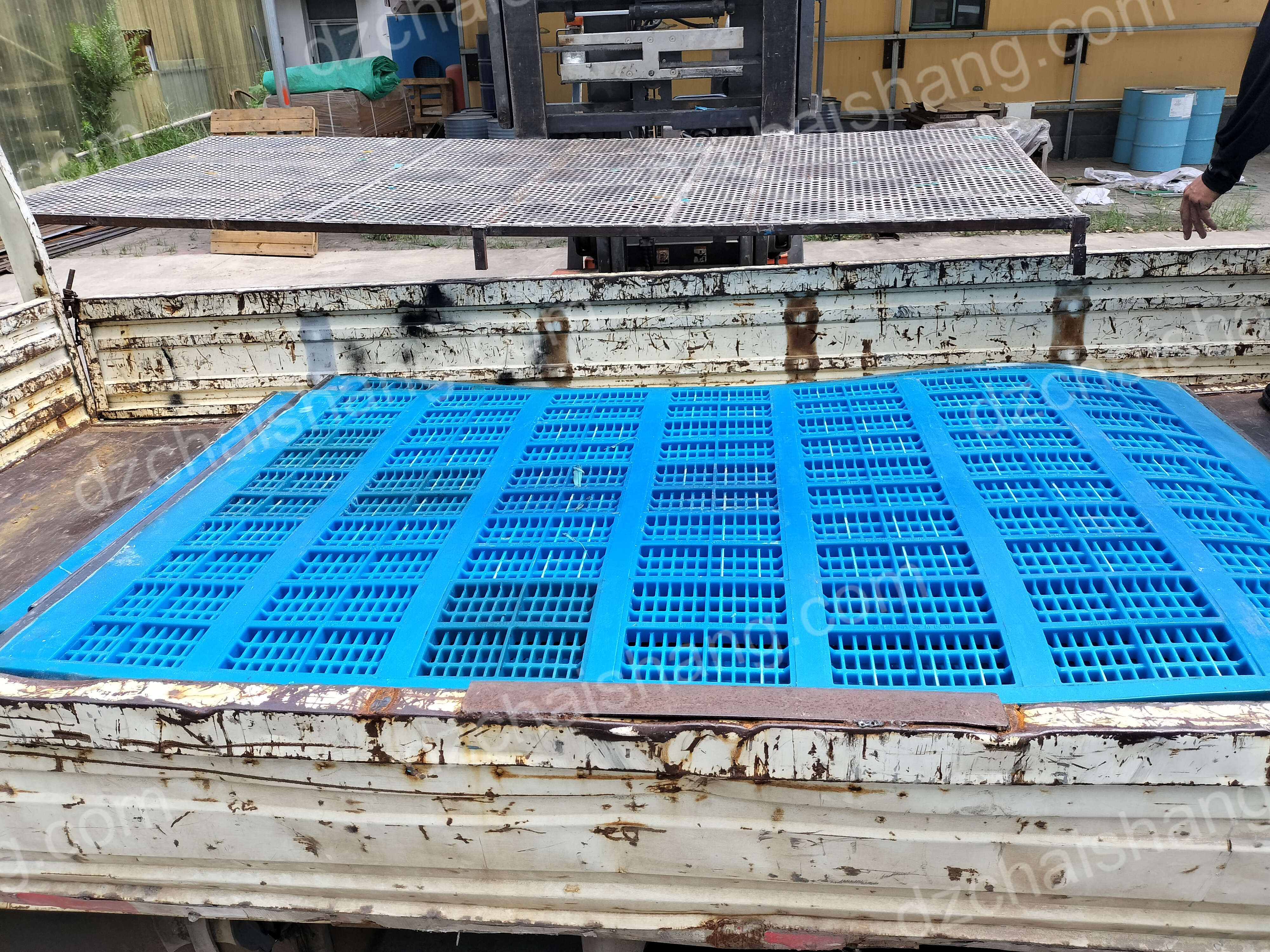

Three methods you need to master to identify “Polyurethane Sieve Plate”

1. Check the aperture ratio of the polyurethane sieve plate. The opening rate is a direct factor that affects the screening rate. The more round holes there are on the polyurethane material screen, the higher the opening rate, and the higher the yield and production capacity of the screen.

2. The connection of polyurethane screen plates is also an aspect we should pay attention to. The connection method of screen panels made of polyurethane material can quickly affect the production of screen panels. Polyurethane screen plates must be inseparably connected to each other, without leakage, and ensure level.

3. Carefully observe the appearance and surface of the polyurethane screen plate, whether the surface is smooth, whether there are polyurethane screen plate colors, broken bars, burrs, insufficient materials, improper materials, tight seams, etc.

The service life of polyurethane screen plates is 8-10 times that of standard metal mesh belts, 3 times that of stainless steel mesh belts, and 3.9 times that of natural rubber mesh belts. It is a screening material with excellent wear resistance. The polyurethane screen manufacturing material is molecular material organic chemical polyurethane elastomer, which has excellent wear resistance and flexibility and can be installed. The materials used to make polyurethane screens are specially treated to ensure that they will not delaminate under prolonged alternating loads.