- 15

- Dec

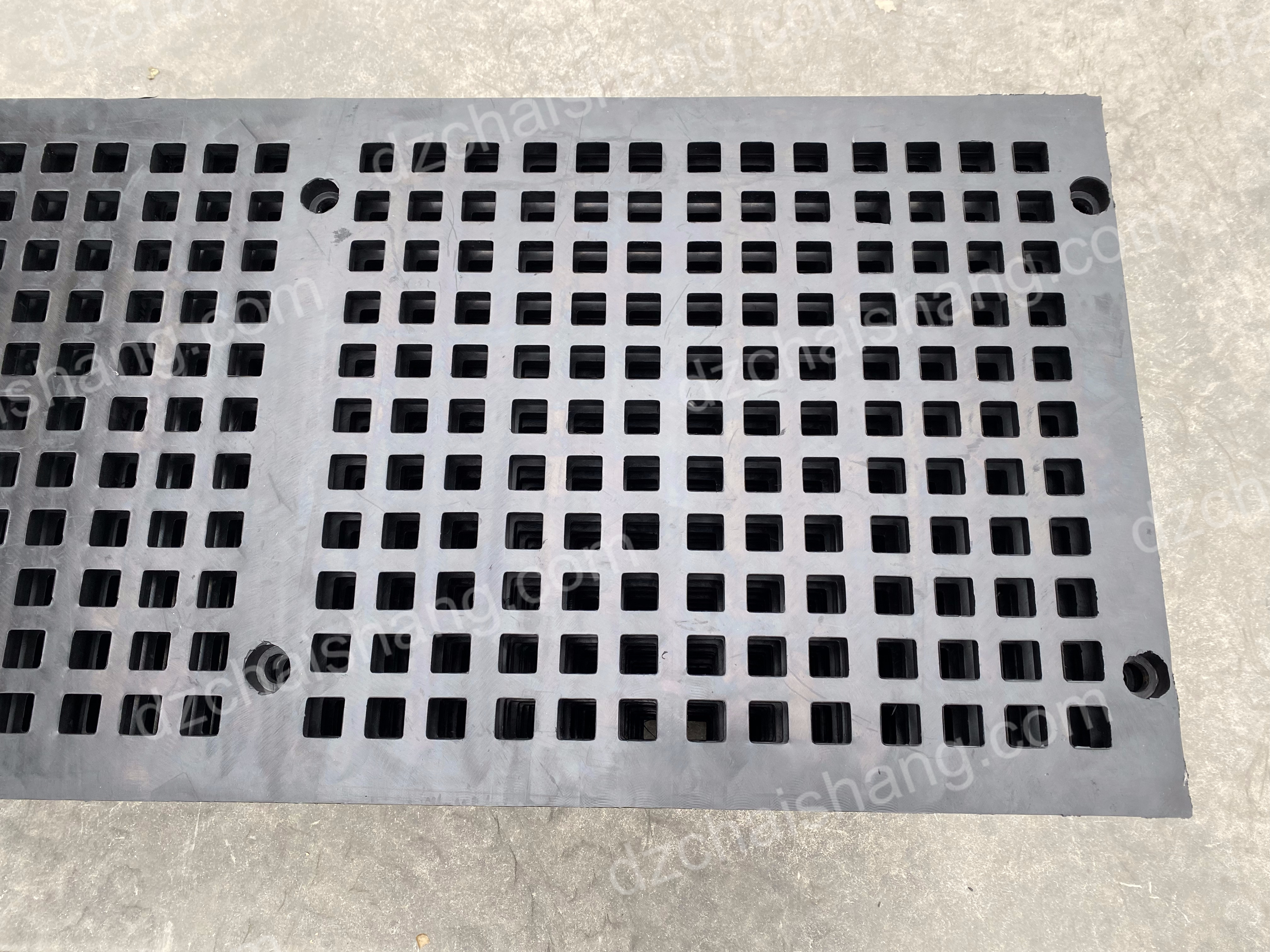

Rubber screen plate production process flow

Rubber screen panels are used in various large and medium-sized environments involving public utilities, such as power plants, low-voltage distribution rooms, distribution stations and suburban electrical work. When working in the field, a parasol should be used to protect the rubber. The screen plates are covered to prevent sunlight, otherwise, manufacturing accidents are likely to occur during use.

If the rubber screen is stored, it should be emptied in a place away from heat and open flames. The following is a brief introduction to the manufacturing process of the rubber screen:

Rubber mesh is made of vulcanized rubber. Vulcanized rubber is used as the raw material for antistatic rubber because it has excellent properties that other materials do not have. Vulcanized rubber is latex extracted from green plants. The ductility of vulcanized rubber is one of the reasons for choosing insulating rubber sheets. Due to its excellent ductility, the insulating rubber sheet is not easy to tear during all processes such as paving, and has excellent flexibility, ductility and ductility.

Rubber mesh is the same as any other insulating material, and different models and specifications of rubber mats have different voltage ratings. Before project construction, the model specifications and specifications are determined according to the natural environment used. If the model does not match the natural environment of the project construction, then the appropriate model specifications and specifications are selected, and the appropriate rubber pad is selected.

Therefore, it is easy to cause personal and economic losses during the entire construction process. Additionally, a certain number of workers must be present during project construction to prevent accidents. During the construction process, relevant electrical construction techniques must be carried out to ensure construction and civilized construction.