- 18

- Jan

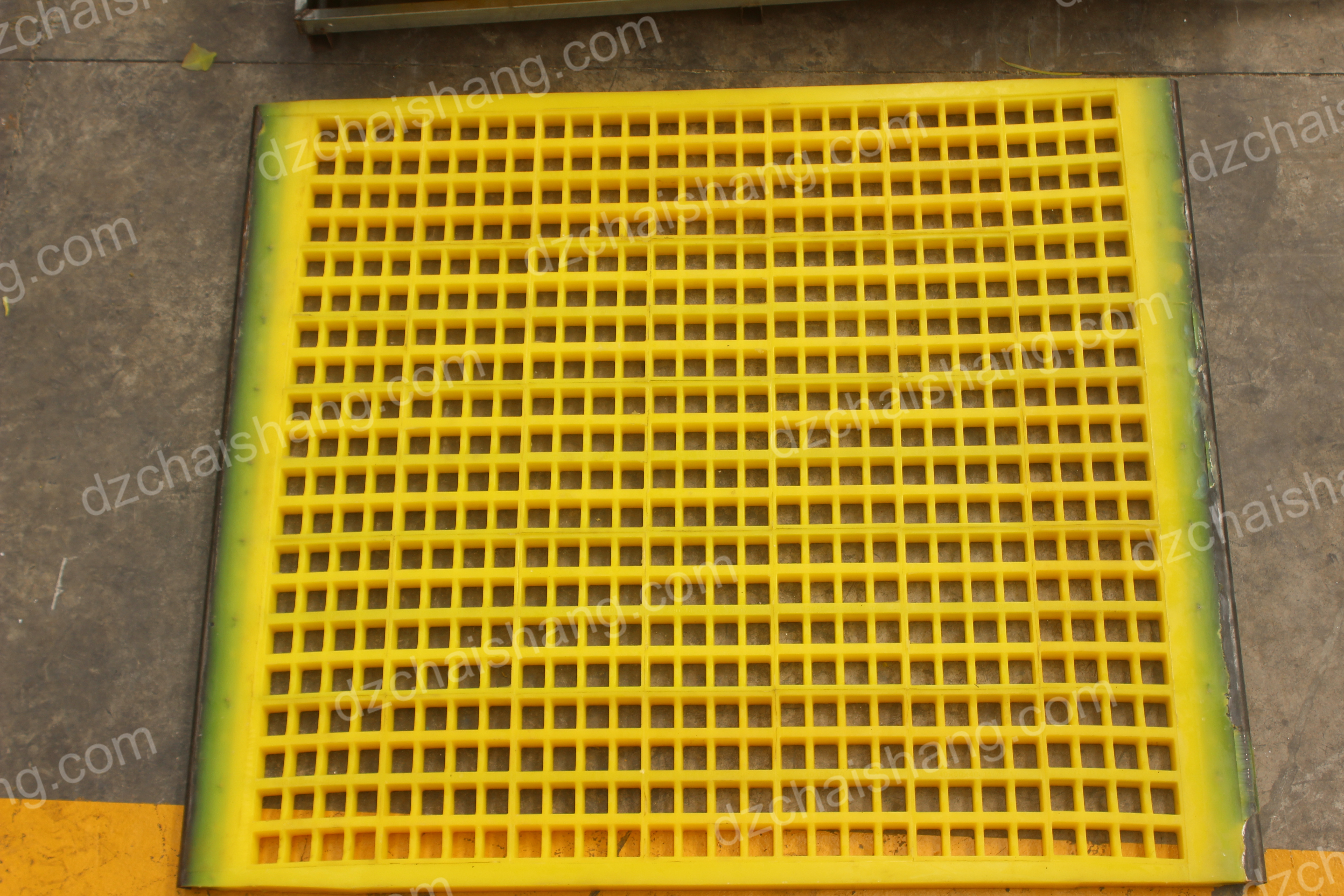

PU tensioned screen Made to order,tensioned PUMedia Custom-made Ore

The Benefits of Using PU Tensioned Screens in Media Applications

PU tensioned screens, also known as polyurethane tensioned screens, are a popular choice for media applications due to their numerous benefits. These screens are custom-made to order, ensuring a perfect fit for any specific requirements. Whether it’s for ore processing, dewatering, or any other media application, PU tensioned screens offer a range of advantages that make them a preferred choice in the industry.

One of the key benefits of PU tensioned screens is their durability. Made from high-quality polyurethane material, these screens are designed to withstand the harsh conditions of media applications. They are resistant to abrasion, corrosion, and impact, ensuring a longer lifespan compared to traditional screens. This durability translates into cost savings for businesses, as they don’t have to frequently replace worn-out screens.

In addition to their durability, PU tensioned screens also offer excellent screening efficiency. The tensioned design of these screens ensures that the material being processed is evenly distributed across the entire surface, maximizing the screening area. This results in a more efficient separation of particles, leading to higher productivity and throughput. Whether it’s separating fine particles or larger chunks of ore, PU tensioned screens deliver reliable and accurate screening performance.

Another advantage of PU tensioned screens is their versatility. These screens can be customized to meet specific requirements, such as different opening sizes, shapes, and configurations. This flexibility allows businesses to optimize their screening processes and achieve the desired results. Whether it’s achieving a specific particle size distribution or improving the overall efficiency of the operation, PU tensioned screens can be tailored to meet these goals.

Furthermore, PU tensioned screens offer excellent wear resistance. The polyurethane material used in these screens is highly resistant to wear, ensuring that they maintain their performance even after prolonged use. This wear resistance is particularly important in media applications where the screens are constantly exposed to abrasive materials. By choosing PU tensioned screens, businesses can minimize downtime and maintenance costs associated with screen replacements.

In terms of installation and maintenance, PU tensioned screens are relatively easy to handle. They can be quickly and securely installed onto the screening equipment, ensuring minimal downtime during the setup process. Additionally, these screens are easy to clean and maintain, thanks to their smooth surface and non-stick properties. Regular cleaning and maintenance of PU tensioned screens can help prolong their lifespan and ensure optimal performance.

In conclusion, PU tensioned screens offer a range of benefits that make them an ideal choice for media applications. Their durability, screening efficiency, versatility, and wear resistance make them a reliable and cost-effective solution for businesses in various industries. Whether it’s ore processing, dewatering, or any other media application, PU tensioned screens can deliver the desired results. By investing in these custom-made screens, businesses can improve their screening processes, increase productivity, and reduce maintenance costs in the long run.