- 24

- Jan

Discussion on structural design of mining rubber screen

Introduction

This discussion focuses on the structural design of mining rubber screens.

Overview of Mining Rubber Screens in Structural Design

Mining rubber screens play a crucial role in the mining industry, as they are responsible for separating valuable minerals from waste materials. The structural design of these screens is of utmost importance, as it directly affects their efficiency and durability. In this article, we will provide an overview of the structural design of mining rubber screens, discussing the key factors that need to be considered.

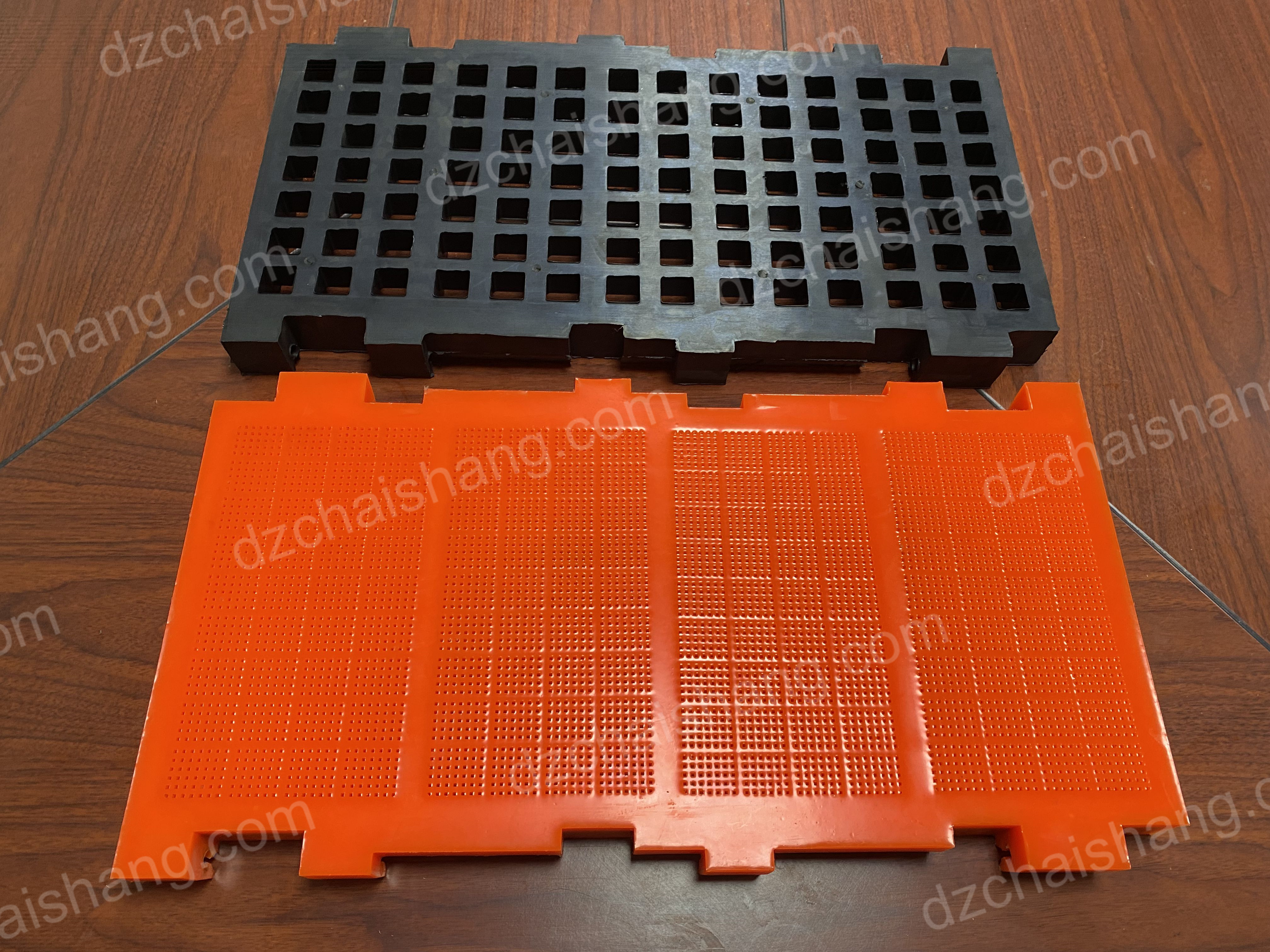

One of the primary considerations in the structural design of mining rubber screens is the material used. Rubber is the preferred choice due to its excellent wear resistance and flexibility. It can withstand the harsh conditions of the mining environment, including abrasive materials and high impact forces. Additionally, rubber screens are known for their self-cleaning properties, which prevent clogging and improve screening efficiency.

The shape and size of the screen panels are also crucial aspects of the structural design. The panels are typically rectangular or square, with various dimensions available to suit different mining applications. The size of the openings in the screen panels, known as the aperture size, is carefully determined based on the desired particle size separation. Smaller aperture sizes are used for finer particle separation, while larger sizes are suitable for coarser materials.

To ensure optimal performance, the structural design of mining rubber screens must also consider the tensioning system. Tensioning is necessary to maintain the proper tension of the screen panels, preventing sagging or loosening during operation. Various tensioning methods are available, including modular tensioning systems and bolted tensioning systems. The choice of tensioning system depends on factors such as screen size, installation requirements, and maintenance considerations.

Another important aspect of the structural design is the support structure. The support structure provides stability and rigidity to the screen panels, ensuring they can withstand the forces exerted during operation. It is typically made of steel or other sturdy materials and is designed to withstand the weight of the screen panels and the material being screened. The support structure must be carefully engineered to prevent excessive vibrations and ensure smooth operation.

In addition to the material, shape, size, tensioning system, and support structure, the structural design of mining rubber screens must also consider factors such as the angle of inclination and the flow rate of the material being screened. The angle of inclination affects the screening efficiency, as it determines the trajectory of the material on the screen surface. The flow rate, on the other hand, determines the amount of material that can be processed per unit of time. Both factors need to be carefully considered to optimize the performance of the screens.

In conclusion, the structural design of mining rubber screens is a critical aspect that directly impacts their efficiency and durability. The choice of material, shape, size, tensioning system, support structure, angle of inclination, and flow rate all play a significant role in ensuring optimal performance. By carefully considering these factors, mining companies can select and design screens that meet their specific requirements and enhance their overall productivity.