- 24

- Jan

What should I do if the vibrating screen mesh is blocked or damaged?

Introduction

If the vibrating screen mesh is blocked or damaged, there are several steps you can take to address the issue.

Troubleshooting Tips for Blocked Vibrating Screen Mesh

What should I do if the vibrating screen mesh is blocked or damaged?

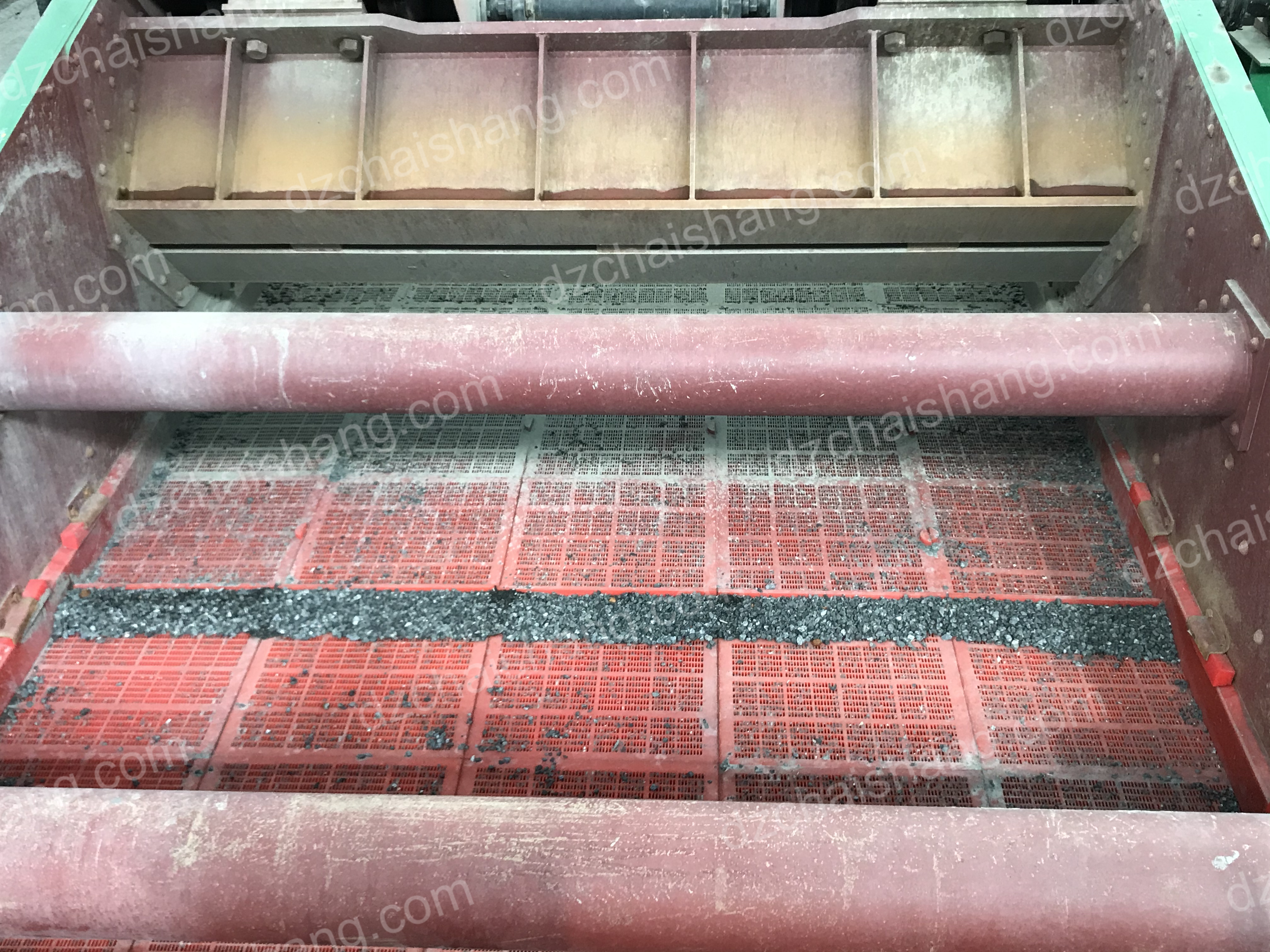

Vibrating screens are widely used in various industries for separating and grading materials. However, over time, the screen mesh can become blocked or damaged, affecting the efficiency and performance of the vibrating screen. In this article, we will discuss some troubleshooting tips for dealing with blocked vibrating screen mesh.

One common issue with vibrating screens is the blockage of the screen mesh. This can occur due to various reasons, such as the accumulation of fine particles or the presence of sticky materials. When the screen mesh is blocked, the material cannot pass through, resulting in reduced productivity and increased downtime.

To address this issue, the first step is to identify the cause of the blockage. If the blockage is caused by fine particles, it can be resolved by cleaning the screen mesh. This can be done by using a brush or compressed air to remove the particles from the mesh. It is important to be gentle while cleaning to avoid damaging the mesh.

In some cases, the blockage may be caused by sticky materials that adhere to the screen mesh. In such situations, it is recommended to use water or a cleaning solution to remove the sticky substances. However, it is important to ensure that the cleaning solution is compatible with the screen mesh material to avoid any damage.

If cleaning the screen mesh does not resolve the blockage issue, it may be necessary to replace the mesh. Over time, the screen mesh can become worn out or damaged, affecting its performance. When replacing the mesh, it is important to choose a high-quality mesh that is suitable for the specific application. Additionally, proper installation of the new mesh is crucial to ensure optimal performance.

Another troubleshooting tip for dealing with blocked vibrating screen mesh is to adjust the screen tension. The tension of the screen mesh plays a crucial role in its performance. If the tension is too loose, the mesh may sag, leading to blockage. On the other hand, if the tension is too tight, it may cause excessive wear and tear on the mesh. Therefore, it is important to find the right balance and adjust the tension accordingly.

Regular maintenance and inspection of the vibrating screen can help prevent blockage and damage to the screen mesh. It is recommended to schedule routine inspections to check for any signs of wear or damage. Additionally, keeping the screen clean and free from debris can also help maintain its performance.

In conclusion, dealing with a blocked or damaged vibrating screen mesh requires proper troubleshooting and maintenance. Cleaning the mesh, using appropriate cleaning solutions, and adjusting the tension are some of the steps that can be taken to address blockage issues. If the blockage persists, replacing the mesh may be necessary. Regular maintenance and inspection can help prevent blockage and ensure the optimal performance of the vibrating screen.