- 20

- Mar

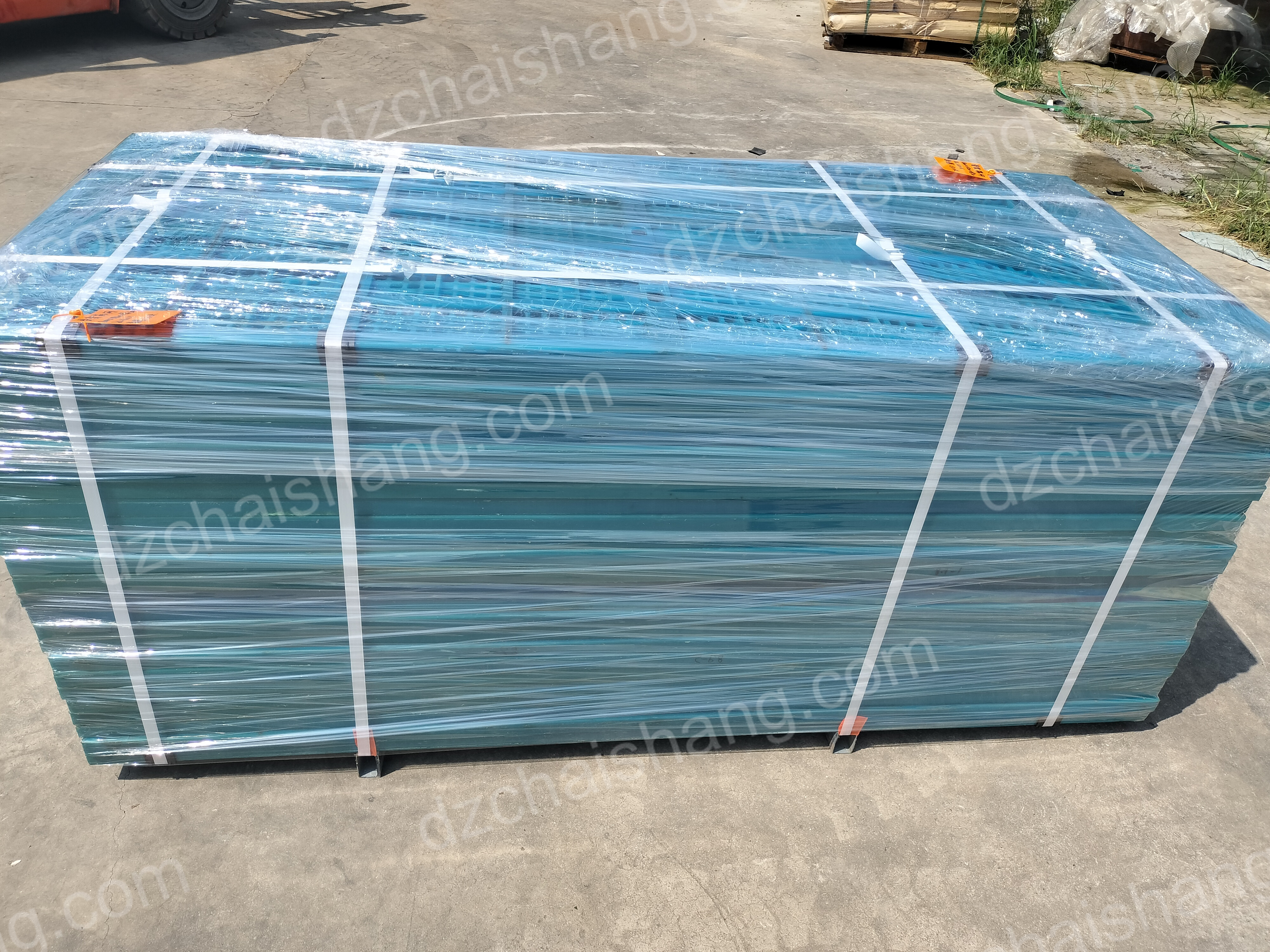

Factory vibrating Urethane screen mesh Mining

Introduction

Factory vibrating urethane mesh mining is a process used in the mining industry to separate and classify materials based on size. This technology utilizes urethane mesh screens that vibrate to efficiently separate particles of different sizes, allowing for more precise and effective mineral processing.

Benefits of Using Factory Vibrating Urethane Mesh in Mining Operations

In the mining industry, efficiency and productivity are key factors in ensuring successful operations. One technology that has revolutionized the way mining companies process materials is the factory vibrating urethane mesh. This innovative mesh design offers a range of benefits that can significantly improve the efficiency and effectiveness of mining operations.

One of the primary advantages of using factory vibrating urethane mesh is its durability and longevity. Made from high-quality urethane material, this mesh is designed to withstand the harsh conditions of mining operations, including abrasive materials and high-impact forces. This durability ensures that the mesh can withstand the rigors of daily use, reducing the need for frequent replacements and maintenance.

In addition to its durability, factory vibrating urethane mesh is also known for its superior screening capabilities. The unique design of the mesh allows for efficient separation of materials, resulting in a more precise and accurate screening process. This can help mining companies achieve higher levels of product quality and consistency, ultimately leading to increased profitability.

Furthermore, factory vibrating urethane mesh offers improved efficiency in the screening process. The vibrating motion of the mesh helps to quickly and effectively separate materials, reducing processing times and increasing throughput. This can result in significant cost savings for mining companies, as well as improved overall productivity.

Another key benefit of using factory vibrating urethane mesh is its versatility. This mesh can be customized to meet the specific needs of different mining operations, allowing for greater flexibility and adaptability. Whether screening fine particles or larger materials, this mesh can be tailored to provide optimal performance in a variety of applications.

Moreover, factory vibrating urethane mesh is easy to install and maintain, further enhancing its appeal to mining companies. The simple design of the mesh allows for quick and hassle-free installation, minimizing downtime and maximizing operational efficiency. Additionally, the durable nature of the mesh reduces the need for frequent maintenance, saving time and resources in the long run.

Overall, the benefits of using factory vibrating urethane mesh in mining operations are clear. From its durability and longevity to its superior screening capabilities and efficiency, this mesh offers a range of advantages that can help mining companies improve their operations and achieve greater success. By investing in this innovative technology, mining companies can enhance their productivity, reduce costs, and ultimately increase their profitability in the competitive mining industry.