- 23

- Mar

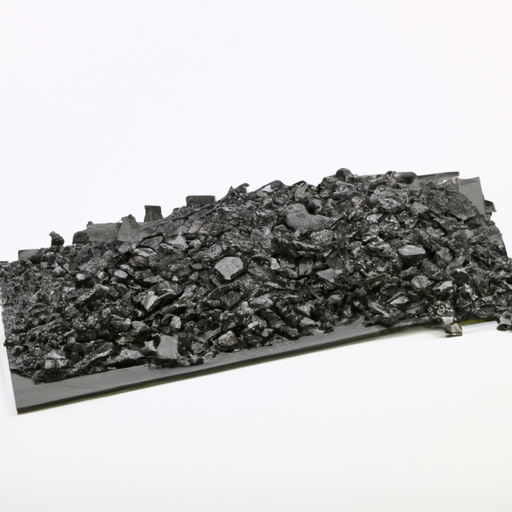

High Quality vibrating Polyurethane tensioned Deck Aggregate

Introduction

High Quality vibrating Polyurethane tensioned Deck Aggregate is a durable and efficient solution for screening and separating materials in various industries. Its high-quality construction and tensioned design ensure optimal performance and longevity in demanding applications.

Benefits of Using High Quality Vibrating Polyurethane Tensioned Deck Aggregate

High quality vibrating polyurethane tensioned deck aggregate is a crucial component in the mining and aggregate industries. This type of aggregate is known for its durability, flexibility, and efficiency in separating materials. In this article, we will explore the benefits of using high-quality vibrating polyurethane tensioned deck aggregate in various applications.

One of the key advantages of using high-quality vibrating polyurethane tensioned deck aggregate is its superior wear resistance. Polyurethane is a material known for its exceptional durability and ability to withstand harsh conditions. When used in vibrating screens, polyurethane tensioned decks can last significantly longer than traditional wire mesh screens. This results in reduced downtime for maintenance and replacement, ultimately leading to cost savings for the operation.

In addition to its wear resistance, high-quality vibrating polyurethane tensioned deck aggregate offers excellent flexibility. The flexibility of polyurethane allows for greater screening efficiency and improved material separation. This flexibility also enables the screen to better conform to the material being processed, resulting in higher throughput and more accurate sizing.

Furthermore, polyurethane tensioned decks are known for their self-cleaning properties. The smooth surface of polyurethane prevents material buildup and blinding, ensuring continuous operation and consistent performance. This self-cleaning feature is especially beneficial in applications where sticky or wet materials are being processed, as it helps prevent clogging and maintain optimal screening efficiency.

Another advantage of using high-quality vibrating polyurethane tensioned deck aggregate is its noise reduction capabilities. Polyurethane is a quiet material that absorbs vibration and reduces noise levels during operation. This is particularly important in environments where noise pollution is a concern, such as residential areas or indoor facilities. By using polyurethane tensioned decks, operators can create a quieter and more comfortable working environment for their employees.

Additionally, high-quality vibrating polyurethane tensioned deck aggregate offers improved screening accuracy. The tight weave of polyurethane screens ensures that even the smallest particles are effectively separated, resulting in a higher quality end product. This level of precision is essential in industries where product quality is paramount, such as in the production of fine aggregates or minerals.

Overall, the benefits of using high-quality vibrating polyurethane tensioned deck aggregate are clear. From superior wear resistance and flexibility to self-cleaning properties and noise reduction, polyurethane tensioned decks offer a range of advantages that can improve the efficiency and performance of screening operations. By investing in high-quality polyurethane tensioned decks, operators can achieve higher throughput, reduced maintenance costs, and a higher quality end product.