- 29

- Apr

Common conveyor cleaners and their characteristics

Belt conveyors use many types of cleaners depending on the site conditions and materials being transported. But they can be roughly divided into three types.

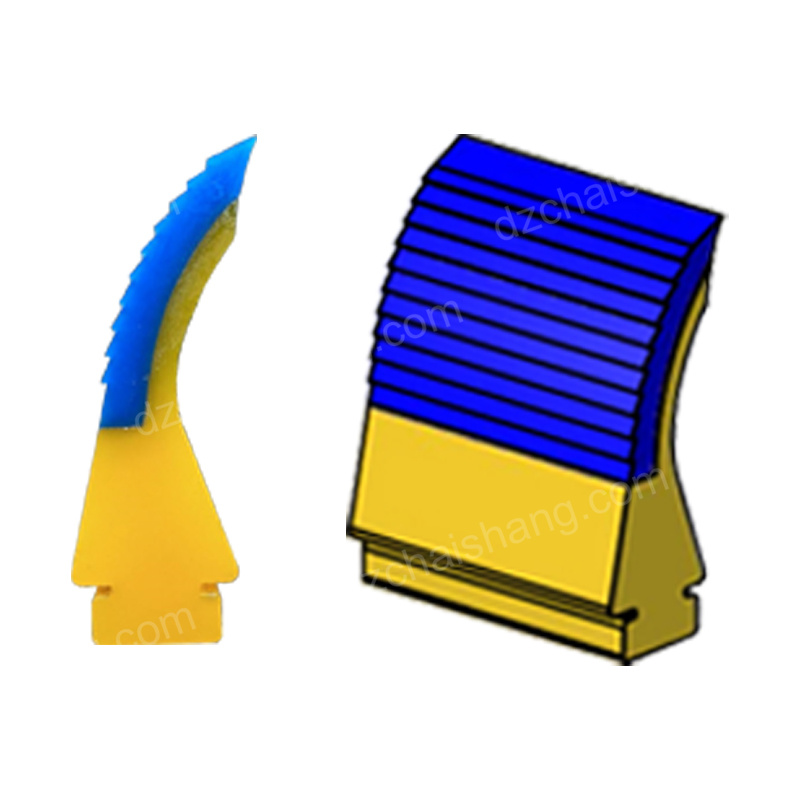

1. Alloy rubber cleaner

The installation position of the alloy rubber cleaner is at the head roller. It is composed of multiple elastic rubber bodies and alloy scraper structures. You only need to adjust the fixed frame and beam shaft to easily adjust the pressure of the scraper and drive roller to the appropriate value. numerical value.

2. Polyurethane cleaner

The scraper made of polyurethane composite material has good following properties for various belts. It is processed and formed in one piece. At the same time, the material itself has high strength and high wear resistance, and has a very stable cleaning effect on the remaining materials on the conveyor belt.

3. Roller brush cleaner

The roller brush cleaner is quite different from the other two cleaners. It does not use a scraper to clean but uses a nylon brush to brush off the residual material particles on the conveyor belt. It is the softest cleaning method and will not scratch the belt. It is maintenance-free. Also very convenient.

Depending on the surrounding environment and the materials being transported. Only by choosing the appropriate cleaner can the conveyor be stable, safe and reliable for a long time.

Author: Deli Zhongbang Roller Lagging https://www.bilibili.com/read/cv14527350/ Source: bilibili