- 12

- Jun

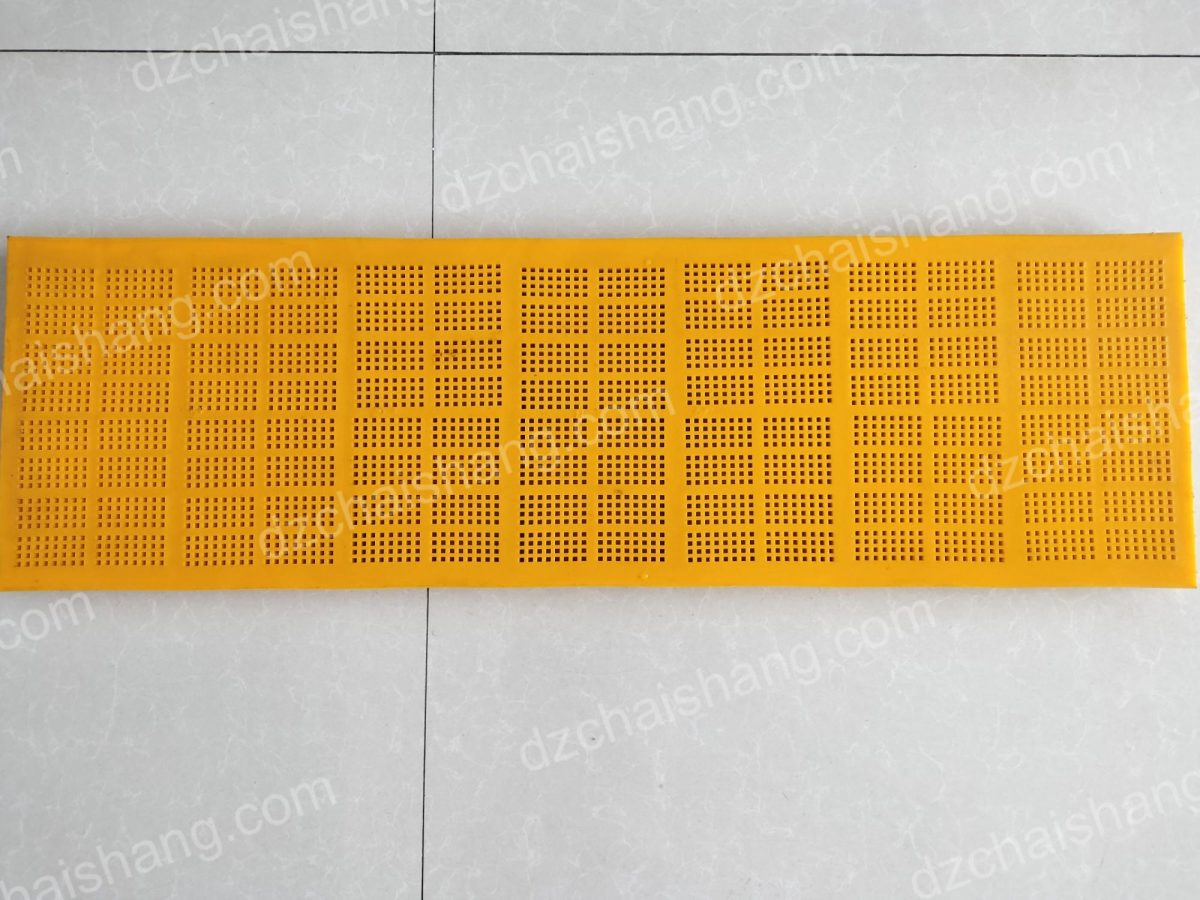

urethane mesh sieve,rubber mesh sieve,mesh plate

Exploring the Benefits and Uses of Urethane Mesh Sieve

The urethane mesh sieve, also known as a rubber mesh sieve or mesh plate, is a versatile tool that has found extensive use in various industries. This article aims to explore the benefits and uses of this innovative product, shedding light on why it has become a preferred choice for many professionals.

The urethane mesh sieve is primarily used for screening and filtering purposes. It is designed to separate particles of different sizes, making it an essential tool in industries such as mining, agriculture, and food processing. The sieve’s mesh design allows for the efficient separation of materials, ensuring that only particles of the desired size pass through.

One of the key benefits of the urethane mesh sieve is its durability. Urethane, also known as polyurethane, is a type of polymer that is known for its toughness and resistance to wear and tear. This makes the sieve highly durable, capable of withstanding heavy use without losing its effectiveness. This durability also translates to cost-effectiveness, as the sieve does not need to be replaced frequently, reducing operational costs in the long run.

Another advantage of the urethane mesh sieve is its flexibility. Unlike metal sieves, which can be rigid and prone to damage, urethane sieves are flexible and can withstand significant pressure without deforming. This flexibility also allows the sieve to adapt to different shapes and sizes of particles, enhancing its filtering efficiency.

The urethane mesh sieve also boasts of excellent resistance to various environmental factors. It is resistant to water, oil, and most chemicals, making it suitable for use in harsh conditions. This resistance also makes the sieve easy to clean, further enhancing its practicality.

In addition to these benefits, the urethane mesh sieve is also environmentally friendly. Urethane is a recyclable material, meaning that old or damaged sieves can be recycled to produce new ones. This not only reduces waste but also contributes to sustainability, making the sieve an eco-friendly choice.

The uses of the urethane mesh sieve are diverse and wide-ranging. In the mining industry, for instance, it is used to separate valuable minerals from unwanted rock and soil. In agriculture, it is used to separate grains and seeds of different sizes. In the food processing industry, it is used to filter out impurities and ensure the purity of the final product. The sieve’s versatility, coupled with its durability and efficiency, makes it a valuable tool in these and many other industries.

In conclusion, the urethane mesh sieve is a versatile, durable, and efficient tool that offers numerous benefits. Its ability to withstand harsh conditions, adapt to different particle sizes, and resist environmental factors makes it a preferred choice for many professionals. Furthermore, its eco-friendly nature and cost-effectiveness make it a sustainable and economical choice. Whether it’s for mining, agriculture, or food processing, the urethane mesh sieve is a tool that delivers exceptional performance and value.

Comparative Analysis: Rubber Mesh Sieve vs Mesh Plate

In the realm of industrial sieving and filtration, the choice of material is of paramount importance. The material not only determines the durability and efficiency of the sieve but also its suitability for specific applications. Among the various materials available, urethane and rubber have emerged as popular choices for mesh sieves, while mesh plates are also widely used. This article aims to provide a comparative analysis of rubber mesh sieves, urethane mesh sieves, and mesh plates, highlighting their unique features, benefits, and potential drawbacks.

Urethane, also known as polyurethane, is a type of polymer that is highly resistant to abrasion, cutting, and tearing. Urethane mesh sieves are known for their durability and longevity, even under harsh operating conditions. They are also resistant to water, oil, and most solvents, making them suitable for a wide range of applications. Moreover, urethane mesh sieves offer excellent flexibility, which allows them to maintain their shape and structural integrity even when subjected to heavy loads or high pressure. This flexibility also makes urethane mesh sieves less prone to clogging, thereby enhancing their efficiency.

On the other hand, rubber mesh sieves are renowned for their elasticity and resilience. They can withstand significant stretching and deformation without losing their original shape. This makes rubber mesh sieves ideal for applications that involve large, heavy particles or high-impact processes. Rubber is also resistant to a variety of chemicals, enhancing its durability and lifespan. However, rubber mesh sieves may not be as resistant to cutting and abrasion as their urethane counterparts, which could limit their suitability for certain applications.

Mesh plates, meanwhile, are typically made of metal or plastic and feature a rigid, flat surface with a grid-like pattern of holes. They offer a high level of durability and strength, making them suitable for heavy-duty applications. Mesh plates are also easy to clean and maintain, which can reduce downtime and increase productivity. However, they lack the flexibility and elasticity of rubber and urethane mesh sieves, which can make them less effective at preventing clogging and maintaining consistent filtration performance.

In terms of cost, urethane and rubber mesh sieves tend to be more expensive than mesh plates due to their superior flexibility and resilience. However, their longer lifespan and lower maintenance requirements can offset the higher initial cost over time. Mesh plates, while cheaper upfront, may require more frequent replacement and maintenance, which can increase their total cost of ownership.

In conclusion, the choice between a urethane mesh sieve, a rubber mesh sieve, and a mesh plate depends largely on the specific requirements of the application. Urethane mesh sieves offer excellent durability, flexibility, and resistance to chemicals, making them suitable for a wide range of applications. Rubber mesh sieves provide superior elasticity and resilience, making them ideal for handling large, heavy particles or high-impact processes. Mesh plates, on the other hand, offer high strength and durability at a lower initial cost, but may require more maintenance and replacement over time. Therefore, it is crucial to consider all these factors when choosing the most suitable material for your sieving or filtration needs.