- 22

- Oct

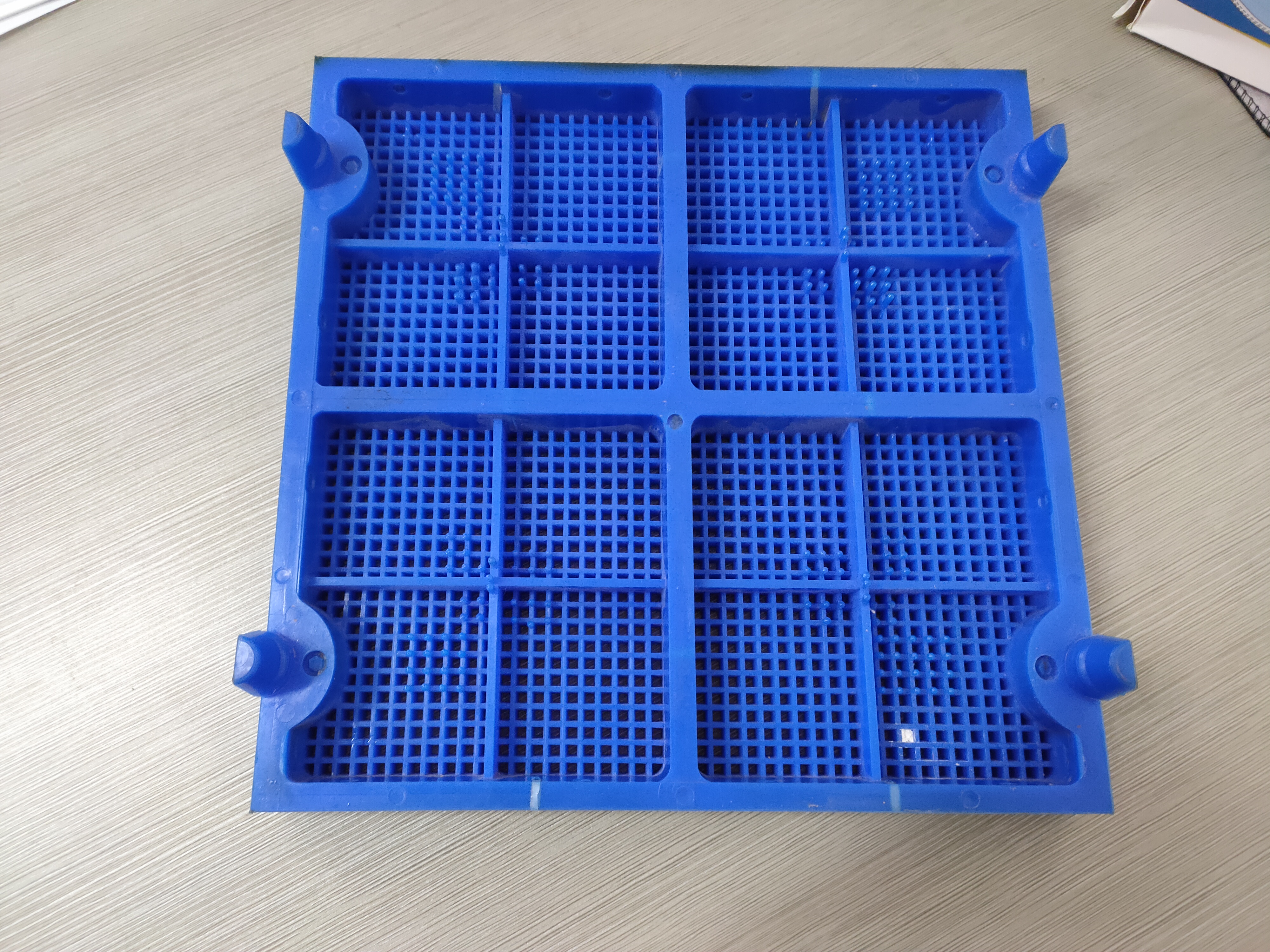

Polyurethane Screen Panels

Polyurethane screen mesh belong to mining equipment used in mines and quarries in combination with vibrating screens, mining equipment and other mining equipment. Suitable for vibrating screens in metallurgy, coal, chemical industry, construction and other industries, used for fine screening and dry screening of bulk materials, it can also be used to classify specific corrosive substances.

www.dzchaishang.com

Polyurethane screen panel can be divided into: relaxation screens, water-passing screens, high-frequency screens, high-frequency dehydration screens, inlaid skeleton screens, etc. according to different uses.

1. Excellent moisture-proof performance, working as a medium under water conditions, for water, oil and other media, reduce the friction coefficient between polyurethane and materials, promote screen penetration, improve screening efficiency, and avoid wet particles. At the same time, reduce the friction coefficient, thereby reducing wear and extending service life.

2. Corrosion-resistant, non-flammable, non-toxic and odorless.

3. Due to the reasonable screen design and unique screen plate manufacturing process, particles of limited size will not block the screen holes. 7. Excellent vibration absorption performance and strong noise reduction ability, reduce noise, and make the screen material not easy to break during vibration.

4. Good wear resistance and long service life. The wear resistance is 3 to 5 times that of steel mesh and more than 5 times that of ordinary rubber mesh.

5. The maintenance workload is small, the polyurethane screen is not easy to scratch, and the service life is long, which can significantly reduce the maintenance volume and maintenance loss.

6. The total cost is low, the one-time investment of the specification (area) polyurethane screen is higher than that of the stainless steel screen (about 2 times), and the service life is 3 to 5 times that of the stainless steel screen. Due to the small number of repairs and replacements of stainless steel screens, the total cost is low and it is very economical.

7. Due to the secondary vibration characteristics of polyurethane, polyurethane screens have a self-cleaning effect and high screening efficiency.

8. Energy-saving polyurethane has a low proportion and is much lighter than steel screens of the same size, which reduces the load of the screen machine, saves power consumption, and extends the service life of the screen machine.