- 25

- Nov

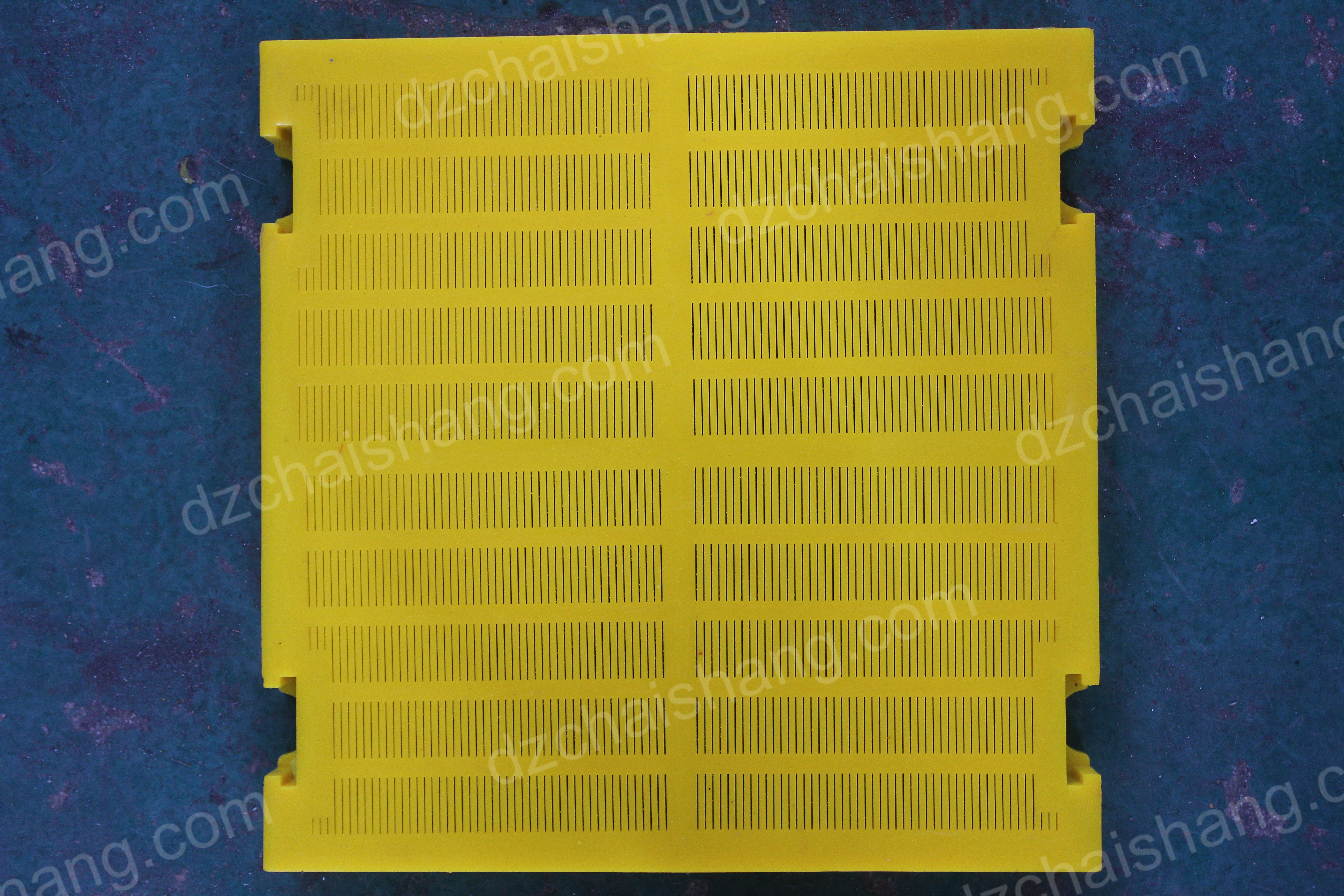

Hebei screen mesh,polyurethane screen panel

Wide range of uses of polyurethane screens

It can be used in metallurgy (iron ore, limestone, fluorite, cooling blast furnace slag, coke and other raw materials), non-ferrous, yellow, coal, chemical, building materials and hydropower engineering, abrasive waste treatment, quarrying and other industries for washing, screening, grading and other industries. New structural model screen plates with various width specifications and screen hole sizes are especially suitable for occasions with strong impact, high hardness and high wear resistance. Wear-resistant screen plates are used for fine crushing and screening of iron ore, raw coal grading, gold, building materials, and screening of sand and gravel in hydropower and nuclear power projects.

Special characteristics of polyurethane screens

1. Corrosion-resistant, non-flammable, non-toxic and odorless.

2. Due to the reasonable design of the screen holes of the polyurethane screen plate and the unique manufacturing process of the screen plate, particles of different sizes will not block the screen holes.

3. Good vibration absorption performance and strong sound-absorbing ability can reduce noise and make the screened material not easy to break during vibration.

4. Due to the characteristics of polyurethane secondary vibration, the polyurethane sieve plate has a self-cleaning effect, so the screening efficiency is high.

5. Good wear resistance and long service life. Its wear resistance is 3 to 5 times that of steel sieve plates and more than 5 times that of ordinary rubber sieve plates.

6. The maintenance workload is small. The polyurethane sieve plate is not easy to damage and has a long service life, so it can greatly reduce the maintenance volume and shutdown and maintenance losses.

7. Low total cost. Although the one-time investment of polyurethane sieve plates of the same specification (area) is higher than that of stainless steel sieve plates (about 2 times), the life of polyurethane sieve plates is 3 to 5 times that of stainless steel sieve plates, and the number of maintenance and replacement is small, so the total cost is not high, and it is also very cost-effective economically.

8. Good moisture resistance. It can work under the condition of water as the medium. In the case of water, oil and other media, the friction coefficient between polyurethane and materials is reduced, which is more conducive to screening, improves screening efficiency, and avoids the adhesion of wet particles. At the same time, due to the reduction of friction coefficient, wear is reduced and service life is increased.

9. Energy saving and consumption reduction. Polyurethane has a small specific gravity and is much lighter than a steel screen of the same size, thereby reducing the load of the screen machine, saving electricity consumption, and extending the life of the screen machine.