- 25

- Nov

Conveyor belt cleaning,belt conveyor cleaners

In industrial production, the cleaning of conveyor belts is crucial. As an important cleaning equipment, the first-level polyurethane cleaner plays a key role. The following is about the role of the first-level polyurethane cleaner, which provides a reference for the cleaning link in industrial production.

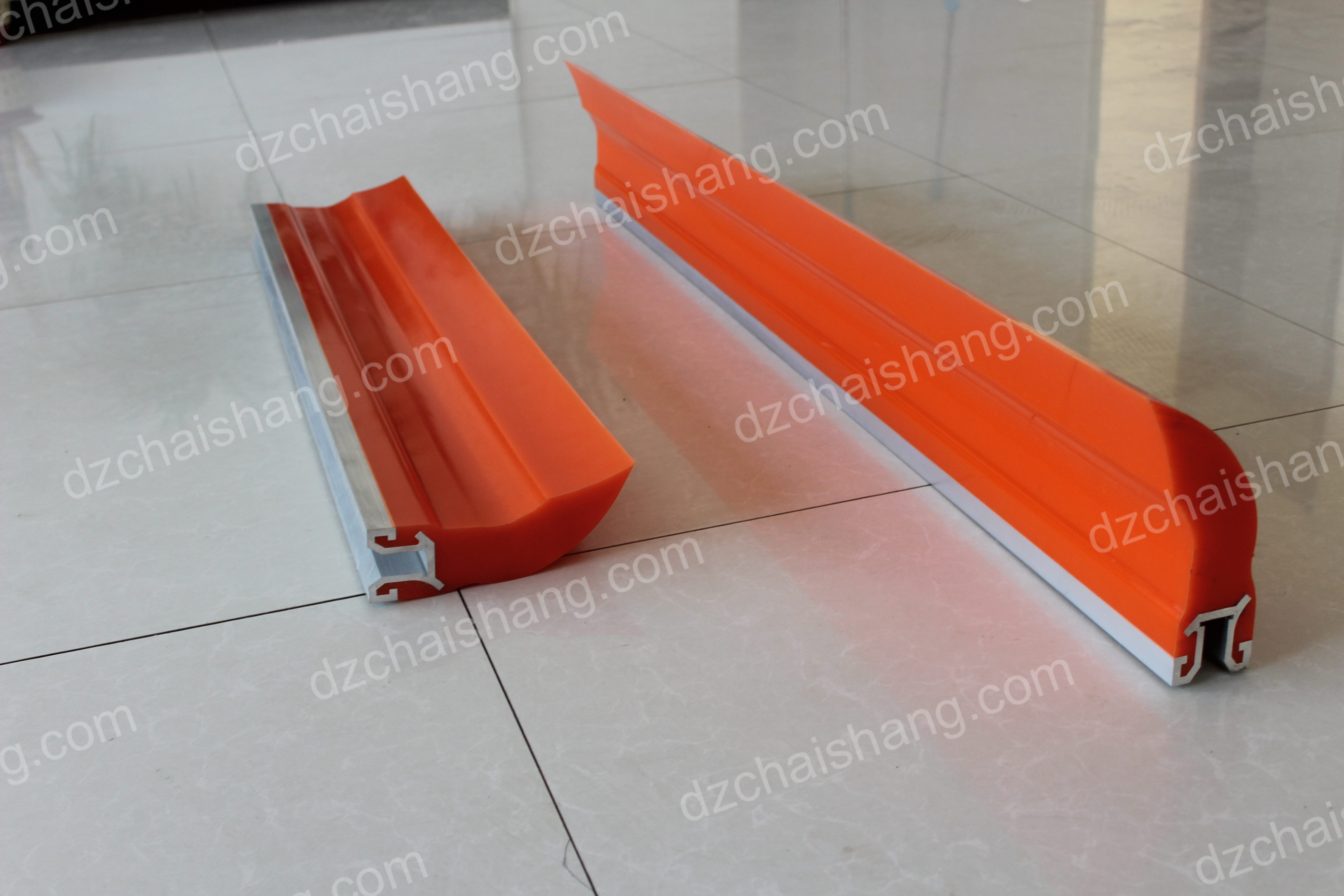

The first-level polyurethane cleaner is usually composed of a polyurethane scraper, a mounting bracket and a tensioning device. It is mainly installed at the head of the conveyor belt to remove the adhered materials on the conveyor belt. Polyurethane materials have the characteristics of high strength, high wear resistance, corrosion resistance and good elasticity, which enables the cleaner to operate stably for a long time in harsh working environments.

The role of the first-level polyurethane cleaner

1. Improve the service life of the conveyor belt

– Remove the adhered materials on the conveyor belt and reduce the wear of the materials on the conveyor belt. Especially for some materials with higher hardness, such as ore, coal, etc., the role of the cleaner is particularly obvious.

– Prevent the accumulation of materials between the conveyor belt and the roller, reduce the wear of the roller, and thus extend the overall service life of the conveyor belt.

2. Ensure the cleanliness of the production environment

– Remove the materials on the conveyor belt in time to avoid material spillage and keep the production site clean. This not only helps to improve work efficiency, but also reduces environmental pollution and meets environmental protection requirements.

– Reduce safety hazards caused by material accumulation, such as slips, trips and other accidents.

3. Improve conveying efficiency

– The sweeper can keep the surface of the conveyor belt clean, reduce the friction between the material and the conveyor belt, and reduce the running resistance of the conveyor belt, thereby improving the conveying efficiency.

– Avoid problems such as conveyor belt deviation caused by material adhesion, and ensure the stable operation of the conveyor belt.

4. Reduce maintenance costs

– Reduce the wear of the conveyor belt and rollers, and reduce the maintenance cost of the equipment.

– Due to the efficient cleaning effect of the sweeper, the workload of manual cleaning is reduced, saving labor costs.

The first-level polyurethane sweeper plays an important role in industrial production. belt conveyor cleaners,It can increase the service life of the conveyor belt, ensure the cleanliness of the production environment, Conveyor belt cleaning,improve the conveying efficiency, belt conveyor cleaners,and reduce the maintenance cost. In practical applications, Conveyor belt cleaning,the appropriate sweeper model and installation location should be selected according to different working environments and material characteristics to give full play to its role. At the same time, belt conveyor cleaners,the sweeper should be regularly maintained and serviced to ensure Conveyor belt cleaning, its stable performance and provide strong guarantee for the efficient operation of industrial production.