- 08

- Nov

In-depth analysis of polyurethane screen cleaning methods

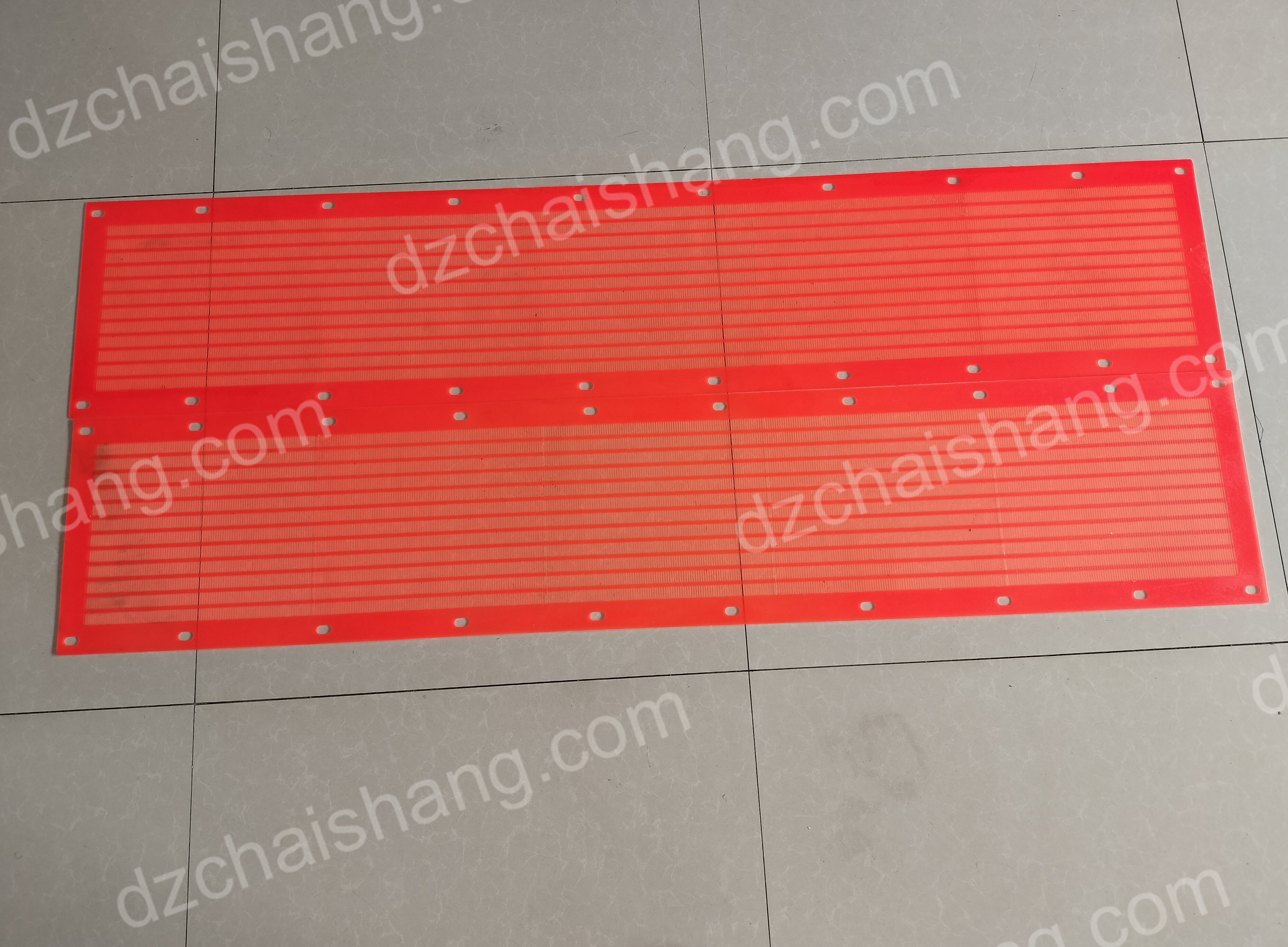

When choosing a polyurethane screen, you must first check whether the mesh openings are average: the mesh openings of high-quality polyurethane mesh are average, comply with specifications, and have a small tolerance range. Look at the opening ratio of the polyurethane screen. The opening rate is the most direct factor affecting screening efficiency: the more openings the polyurethane screen has, the higher the opening rate, and the higher the screening efficiency and output.

Take a look at the connection of the polyurethane screen: The connection method of the polyurethane screen directly affects the screening efficiency. A high-quality polyurethane screen should have moderate stiffness and softness: in practice, the polyurethane screen should have strong elasticity to ensure that there will be no waist collapse during consumption; the polyurethane screen should have a certain toughness to ensure that the screen The net is not fragile.

When choosing a polyurethane screen, it depends on its appearance: whether the appearance of the polyurethane screen is exquisite, whether the screen is flat, whether the color of the polyurethane screen is pure, whether there are broken bars, burrs, missing materials, mixed materials, tight seams, etc. There are two main cleaning methods for polyurethane screens used in papermaking: chemical cleaning and water washing.

The above is an in-depth analysis of polyurethane screen cleaning methods. I hope it helps you.