- 24

- Nov

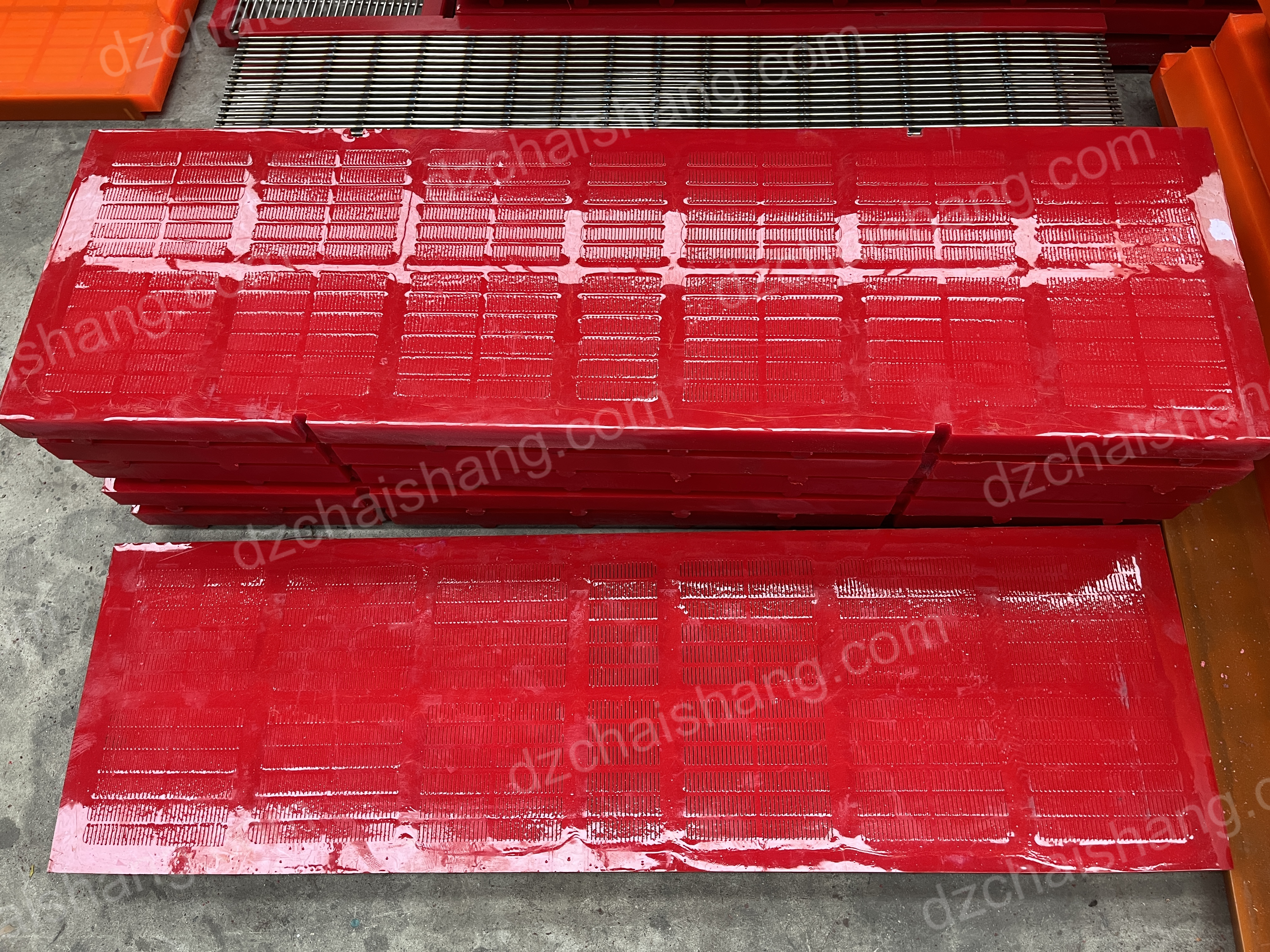

Do you know why the screen plate of the vibrating screen falls off during operation?

Product Name: Vibrating screen mesh

Material: PU/polyurethane/rubber

type:modular/tensioned/high frequency etc.

Popular Dimension: Can be customized.

Customization: Available

Standard service life: 6~12 months

Delivery: 15-45 days depending on the quantity

Email: Jackma@dzchaishang.com

WhatsApp/WeChat: 86-15621266667

Let me show you how to solve the problem of vibrating screen plate falling off during operation. I hope it will be helpful to you.

When the vibrating screen is working, the screen plate will be impacted by the screening materials for a long time during operation. Some screening materials have relatively large particles and have a relatively large impact on the screen plate. So generally in this case, the edge glue of the screen plate will separate from the screen frame in about a month, causing the screen plate to fall off.

After the sieve plate falls off, it takes time to replace it, which affects the screening efficiency. Moreover, during the falling off process, unscreened materials will enter the bin, causing blockage of the pipelines during the screening production process.

In order to solve this problem, the sieve plate adopts splicing technology. The sieve plate is divided into several pieces and spliced together. The joints of the sieve plate are drilled and fixed on the sub-beam of the screening machine with screws. In this way, the sieve plate is Will not cause falling off.

This can also reduce the impact of the material on the sieve plate. If the sieve plate is damaged, just replace that piece, which greatly reduces the replacement amount and extends the service life of the sieve plate!