- 27

- Nov

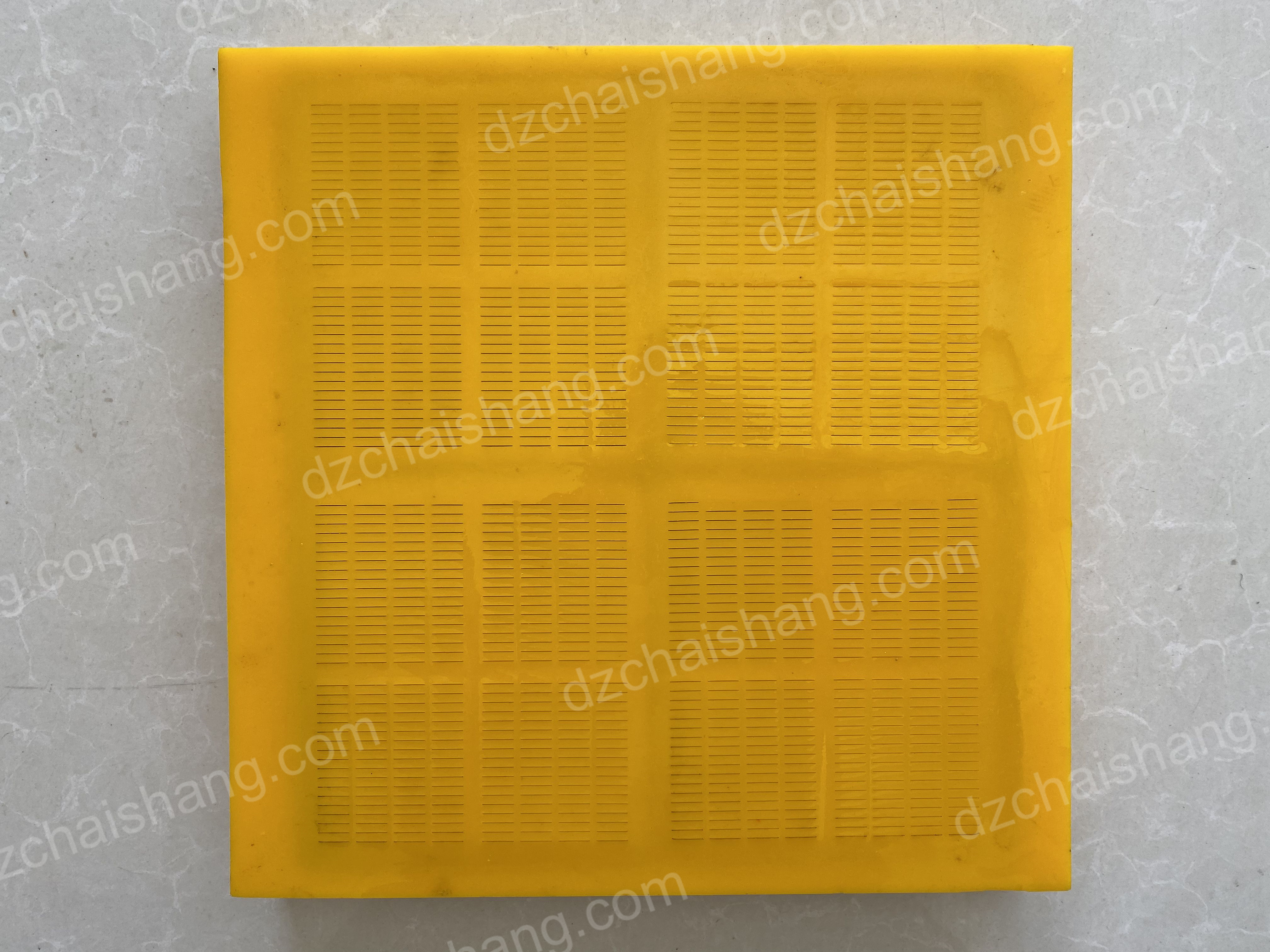

When screening materials, which screen mesh is better, polyurethane or manganese steel?

The differences between “Polyurethane Screen” and “Manganese Steel Screen” help you select the appropriate screen based on the actual needs of the materials to be screened when choosing a screen.

First, the production process: Polyurethane screens use a casting process, generally machine casting and manual casting, both of which require leaving edges, while manganese steel screens are machine-woven or hand-made.

Second, the weight of the product: The raw materials of the polyurethane screen are polymer synthetic materials, which makes the polyurethane screen of the same size much lighter than the manganese steel screen. The light weight consumes less energy for the machine and the load is also Relatively small, extending the service life of the screening machine.

Third, service life: The raw materials for making polyurethane screens have the characteristics of high wear resistance, high strength, high elasticity, and strong load-bearing capacity, which greatly reduces the vibration and impact force between the screening materials and the screen, so it has a long service life. . The service life of polyurethane screen is several to dozens of times that of manganese steel screen.

Fourth, maintenance and replacement: Because the polyurethane screen has a relatively long service life, it greatly reduces the amount of maintenance and replacement during later use. The service life of the manganese steel screen is usually about 3 months, and the number of maintenance and replacement times is There are relatively many.

Fifth, price: Although polyurethane screens are more expensive than manganese steel screens when purchased, if factors such as screening efficiency and service life are comprehensively considered, polyurethane screens can greatly reduce later maintenance and replacement and improve the economy. benefit.