- 29

- Nov

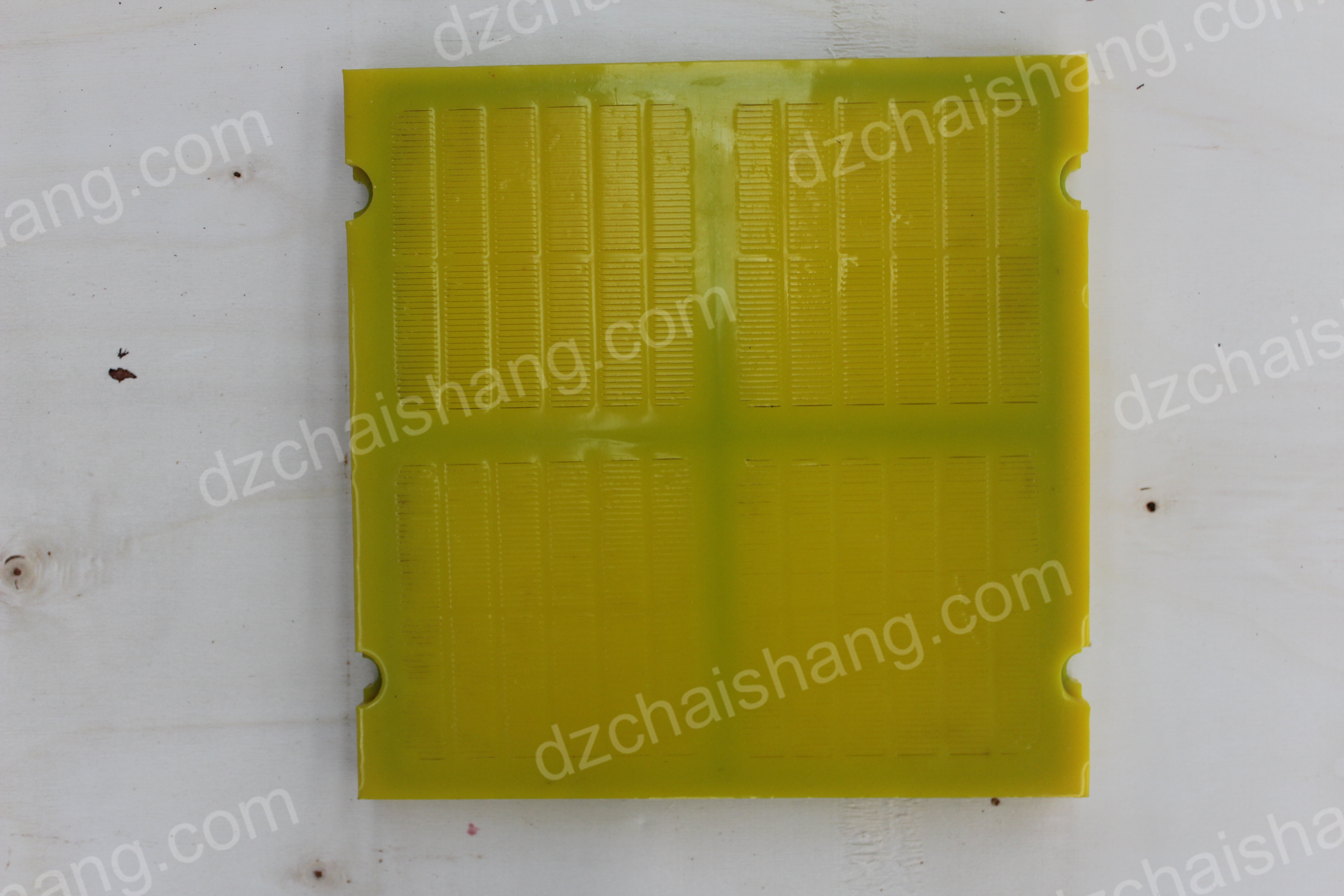

What are the advantages of “polyurethane screen” compared to “traditional screen”?

Everyone knows that polyurethane screen mesh is a common type of screen mesh. With the continuous development of the screen mesh industry, polyurethane screen mesh is used more and more widely. So what are the characteristics of polyurethane screen? How is it different from traditional screens? Come see it today!

The difference between polyurethane screen and traditional screen:

Traditional mining precision screens generally use metal braided or nylon precision screens. Metal braided screens have poor wear resistance and corrosion resistance and are often replaced, resulting in high labor intensity and high cost. Metal screens have poor elasticity and the size of the screen holes is also fixed. of. When screening, it is easy to cause the screen holes to be clogged, affecting the screening power, and causing loud noise during operation.

Nylon precision screens are made of thermoplastic nylon injection molding. Due to the limitations of thermoplastic molecular injection molding technology, large single-piece screens cannot be produced. During use, only small screens can be used to connect them together. Due to the large splicing gap and large screening defects, the screen opening rate is low, usually less than 10%, and the screening force is also extremely low.

Polyurethane screens make up for the shortcomings of traditional screens and have the characteristics of high standards, good elasticity, wear resistance, light weight, long life, low noise, and no need for splicing during use. It has been recognized by the majority of users and is widely used in mining, coal washing, coal, iron ore, metallurgy, water conservancy and other industries!