- 15

- Dec

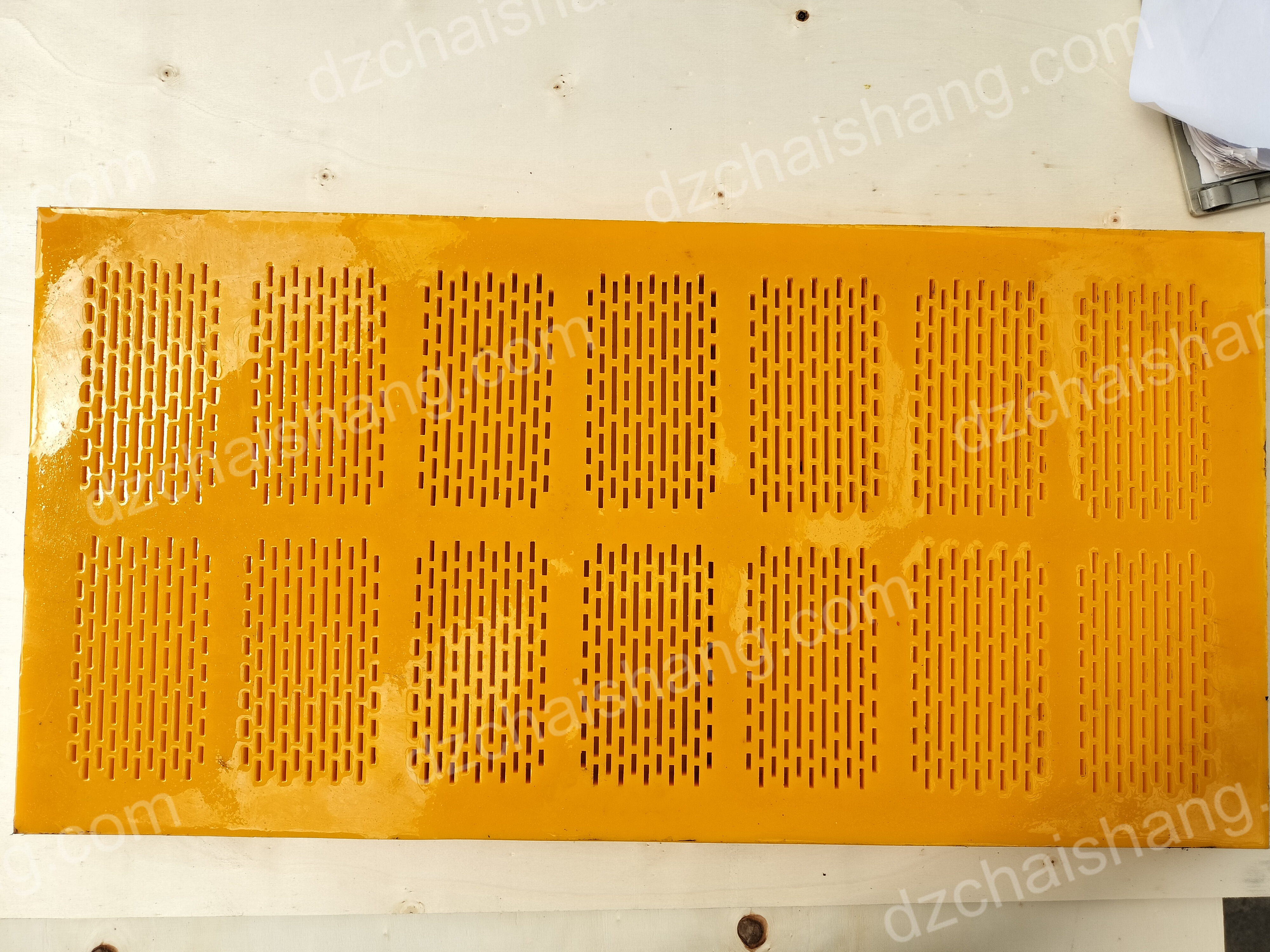

The use and advantages of polyurethane dewatering screen

The manufacturing process of the polyurethane dewatering screen adopts the mold casting process, and the openings are accurate. The screening quality of the polyurethane dewatering screen is high, and the particle size of the materials under the screen can fully meet the user’s requirements and can be achieved.

It is widely used in screening, filtration, dehydration, desliming and other operations in many industries. It has high strength and load-bearing capacity and can be used in various shapes of rigid screening and filtering equipment. The screen has technical parameters such as mesh opening, mesh diameter, aperture, diameter, material, and effective screen surface. The unit of length is usually millimeters (mm). Screens can be used in mining, coal, petroleum, fertilizer, food, environmental protection and other industries, petroleum and salt industries.

The polyurethane dehydration screen works in the presence of water. For media such as water and oil, the friction coefficient between polyurethane and materials is reduced, which is beneficial to screening, improves screening efficiency, and avoids simultaneous reduction. Particle adhesion reduces the friction coefficient, resulting in less wear and long service life.