- 07

- Mar

How to choose the right mining vibrating screen mesh?

Introduction

When choosing the right mining vibrating screen mesh, it is important to consider factors such as material type, aperture size, wire diameter, and weaving style. By understanding these key elements, you can select a mesh that is durable, efficient, and suitable for your specific mining application.

Benefits of Using Mining Vibrating Screen Mesh

Mining vibrating screen mesh is an essential component in the mining industry, as it plays a crucial role in separating and classifying materials. Choosing the right mining vibrating screen mesh is essential to ensure optimal performance and efficiency in mining operations. There are several factors to consider when selecting the appropriate screen mesh for your mining application.

One of the key benefits of using mining vibrating screen mesh is its ability to efficiently separate and classify materials. The mesh is designed to effectively screen out oversized particles and ensure that only the desired material passes through. This helps to improve the overall efficiency of the mining operation by reducing the amount of material that needs to be processed.

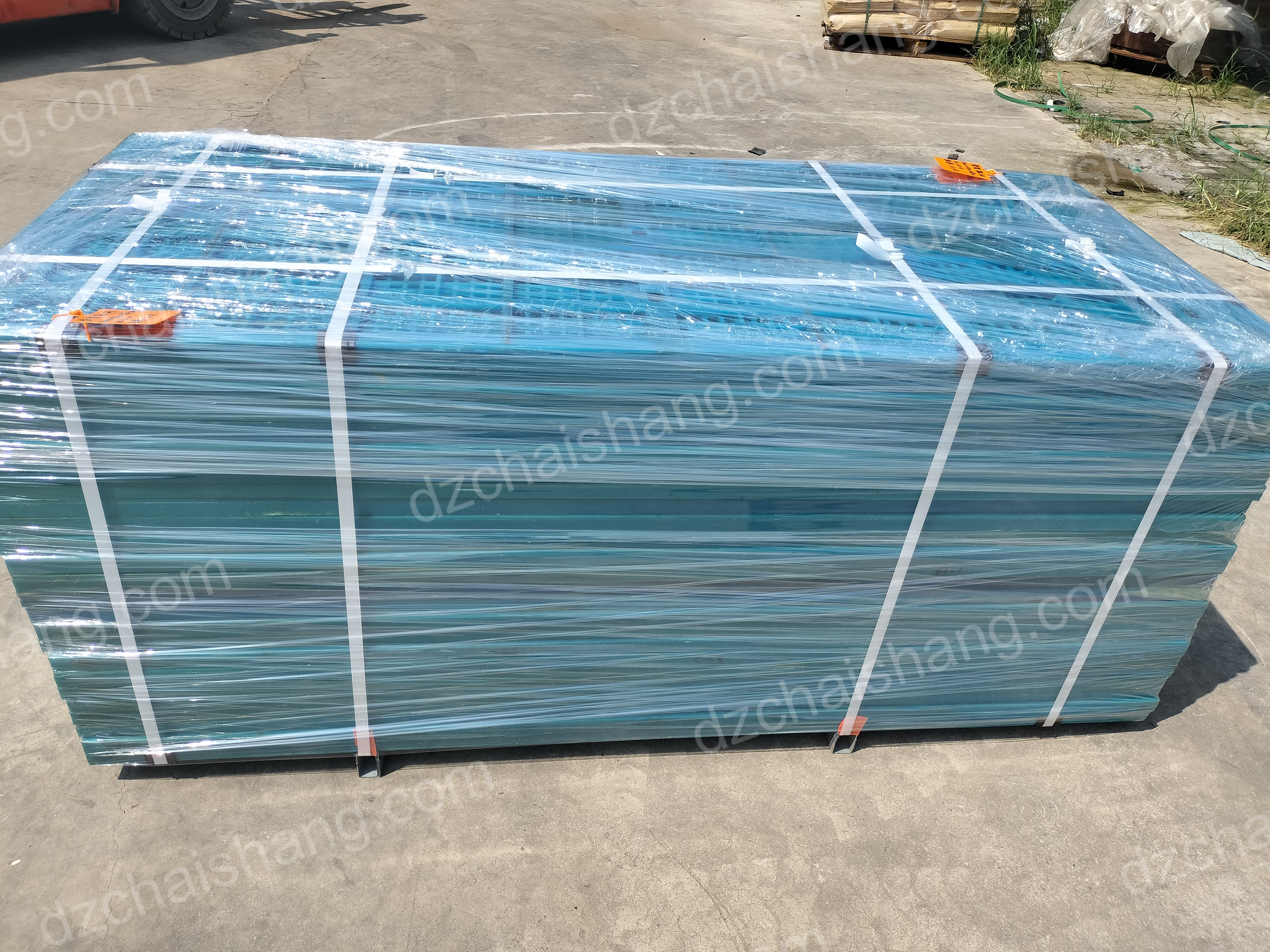

Another benefit of using mining vibrating screen mesh is its durability and longevity. The mesh is typically made from high-quality materials that are resistant to wear and tear, ensuring that it can withstand the harsh conditions of the mining environment. This helps to reduce maintenance costs and downtime, as the screen mesh will not need to be replaced as frequently.

In addition to its durability, mining vibrating screen mesh is also highly customizable. There are a variety of mesh sizes and configurations available, allowing you to choose the right mesh for your specific application. Whether you need a fine mesh for precise classification or a larger mesh for heavy-duty screening, there is a screen mesh option that will meet your needs.

When selecting a mining vibrating screen mesh, it is important to consider the type of material being processed. Different materials have different characteristics, such as size, shape, and density, which can affect the performance of the screen mesh. It is important to choose a mesh that is specifically designed to handle the material you are working with to ensure optimal performance.

Another factor to consider when choosing a mining vibrating screen mesh is the aperture size. The aperture size refers to the space between the wires in the mesh, which determines the size of the particles that can pass through. It is important to choose a mesh with the appropriate aperture size for your application to ensure that it can effectively separate and classify the material.

In addition to aperture size, the wire diameter of the mesh is also an important consideration. The wire diameter affects the strength and durability of the mesh, as well as its ability to withstand the forces of screening. It is important to choose a mesh with a wire diameter that is suitable for the material being processed and the operating conditions of the mining operation.

Overall, choosing the right mining vibrating screen mesh is essential to ensure optimal performance and efficiency in mining operations. By considering factors such as material type, aperture size, and wire diameter, you can select a mesh that meets your specific needs and provides long-lasting durability. With the right screen mesh in place, you can improve the efficiency of your mining operation and achieve better results.