- 28

- Apr

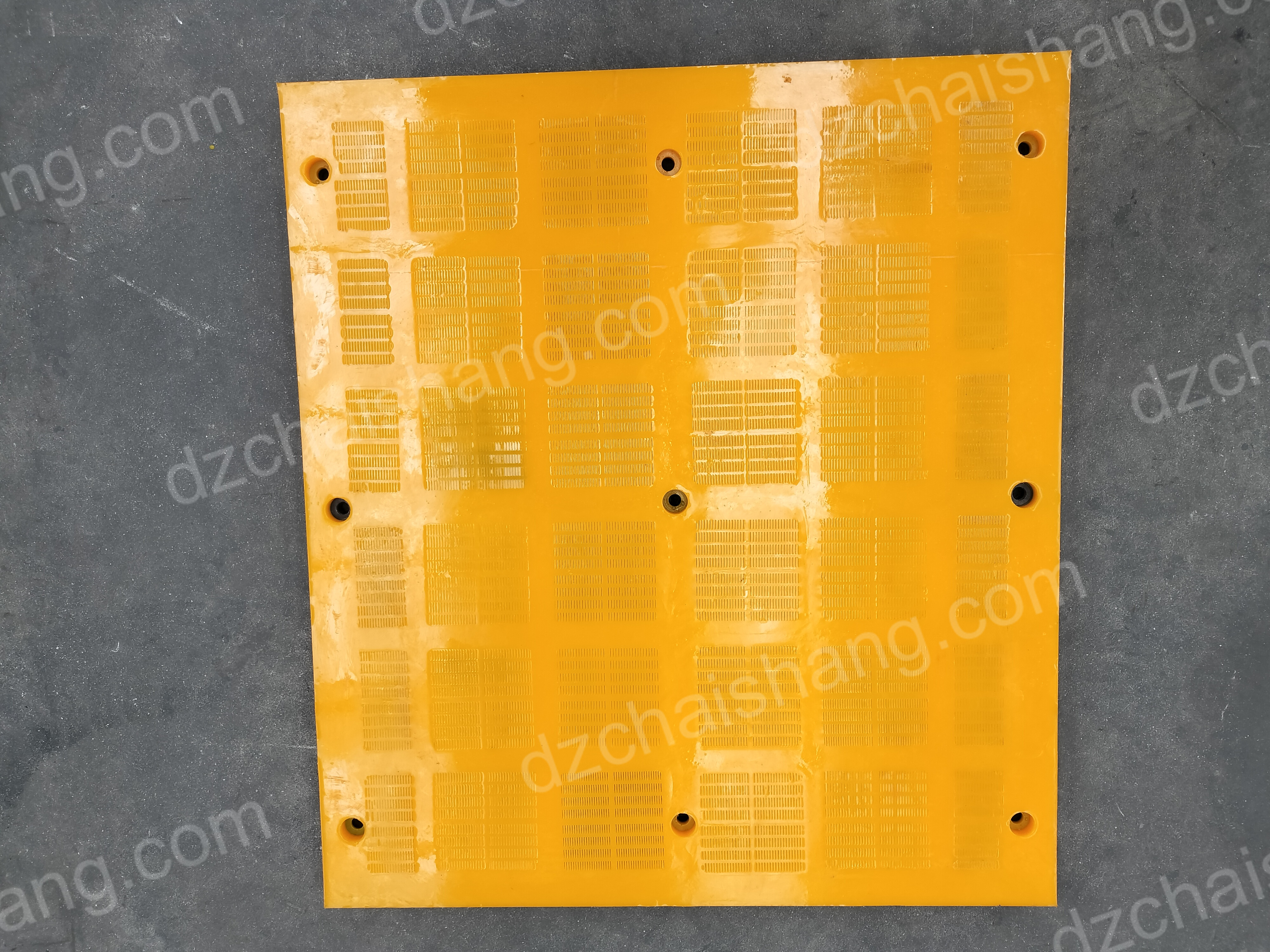

What are the characteristics of polyurethane screen plates?

In modern industrial production, polyurethane screen plates are widely used in petrochemical, forestry chemistry, fertilizer, coal and other fields. It can screen various particulate matter, meet the requirements of material screening and classification, improve production efficiency and reduce production costs. In the future, the application fields of polyurethane screen plates will be more extensive.

Polyurethane screen plate is an efficient screening material with many advantages: Polyurethane screen plate has high compressive strength and wear resistance, and can be used for a long time in high-intensity working environment.

Compared with traditional metal screen plates, it is lighter in weight and easier to install and replace. At the same time, it has good elasticity and can effectively reduce vibration and noise.

It has high screening accuracy and screening efficiency, and can meet the screening requirements of different particle sizes. After a special manufacturing process, its surface also has a certain degree of adhesion, which can effectively avoid particle accumulation and clogging.

Because it has good elasticity and resilience, it can effectively reduce the consumption and impact energy of screening materials, thereby reducing energy consumption and environmental pollution.

Generally speaking, it has the advantages of durability, lightness and convenience, good screening effect, energy saving and environmental protection. Therefore, it has been widely used in screening in fly ash, petroleum, chemical and building materials industries.

It is a sieve plate material with high strength, high toughness, wear resistance and oil resistance. It is widely used in coal, mining, building materials, metallurgy and other fields. With the continuous development of modern industry, the application prospects of polyurethane screen plates are becoming more and more broad.

1. Material advantages of polyurethane screen plate. Its material has the advantages of high strength, high toughness, wear resistance and oil resistance, and is more durable than traditional materials. In addition, polyurethane screen plates are light in specific gravity, easy to process, and can adapt to the needs of various occasions.

2. Application areas of polyurethane screen plates. It is widely used in coal, mining, building materials, metallurgy and other fields, and is often used in screening, filtration, sewage screening and other processes. In addition, polyurethane screen plates can also be used in road construction, sanitation cleaning and other fields.

3. Cost-effectiveness of polyurethane screen plates. Although its material is slightly more expensive, it is wear-resistant, oil-resistant and has a long service life, which can reduce the company’s maintenance costs and replacement frequency, thereby reducing the company’s production costs and improving the company’s economic benefits.

4. The environmental protection advantages of polyurethane screen plates. Polyurethane screen plate material is an environmentally friendly material that does not contain heavy metals and other harmful substances. It does not produce harmful waste gas and waste water during the production process, and complies with national environmental protection requirements.

5. The development prospects of polyurethane screen plates. The application fields of polyurethane screen plates are becoming more and more extensive. In the future, with the continuous advancement of industrial technology, the application prospects of polyurethane screen plates will be even wider. At the same time, polyurethane screen plate production technology will continue to improve, and the performance and quality of materials will be further improved. In short, polyurethane screen plate, as a good screen plate material, will play a more important role in future development.